Text Daniel Giebel ––– Photography

P roviding spare parts for customers is often a challenge in the everyday operations of many companies. Different departments, including engineering and service teams, have to be involved in the process – as do systems that are sometimes superfluous. This makes preparing and managing data a complex task. Cideon Sparify simplifies and standardises this work, thereby reducing the associated outlay significantly. The change process is clearly regulated and linked to the design model. If the design changes, all that is needed is a reboot of the upload. As a result, the updated model is always available on Cideon Sparify almost immediately.

SIMPLE IS BETTER

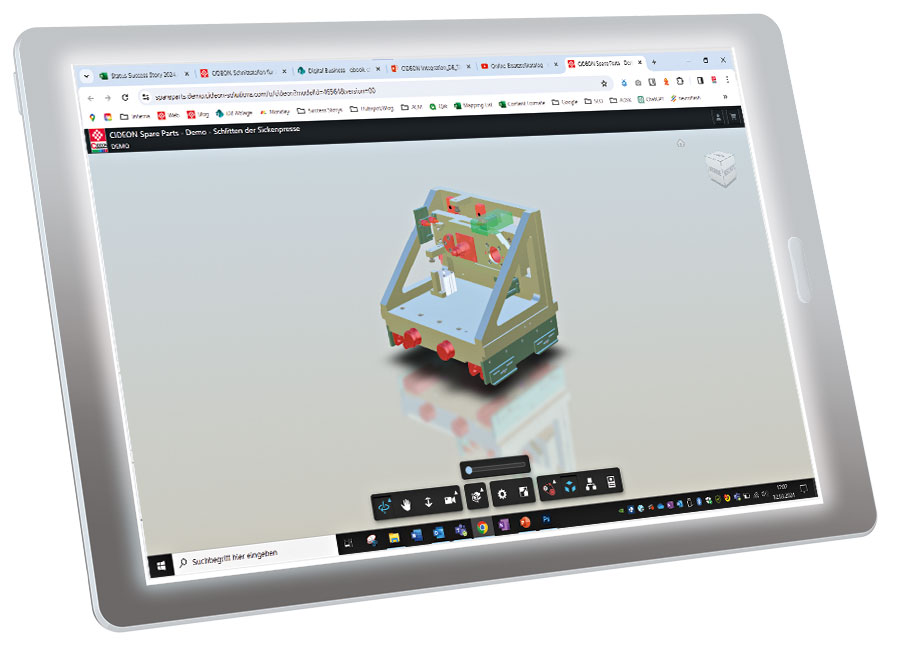

The application, which has been developed based on Autodesk Platform Services, uses the design CAD models from engineering and – where available – PDM data, and visualises these in an online spare parts catalogue. The selection process is extremely easy thanks to the 3D depiction in the spare parts viewer. But that’s not all. If required, the ordering process can also be automated. Rolf Lisse, Managing Director of Cideon, explains: “Lots of information, such as the model number of a spare part, is already in the PDM system. The CAD data are then used to create a 3D view of the product concerned, in which the end customer can directly and clearly identify the spare parts required and select them.” Access can be via a weblink that is provided or through iFrame integration on the manufacturer’s website. This easy user navigation and clear labelling prevent order errors.

FLEXIBLE USE

Cideon Sparify is available in two versions. The “Basic Solution” is used wherever companies have already classified spare parts in a PDM system – preferably Autodesk Vault. The existing spare parts information can then easily be uploaded to the new web application.

If structures first need to be set up, however, it is better to use the “Professional Solution” version of the program. CAD and PDM are first standardised with the help of Cideon Consultants to create a single source of truth, then uploaded to the spare parts viewer. Existing data can therefore be reused to good effect centrally and without requiring any intermediate steps. Where necessary, the software can be customised and expanded, by adding an automated order processing system, for example.