At just 30 kW, things start to get difficult! That’s the point at which air cooling reaches its limits and can no longer remove enough heat from a server rack. AI applications will soon need more than 150 kW of cooling output per rack, though, so what’s the solution?

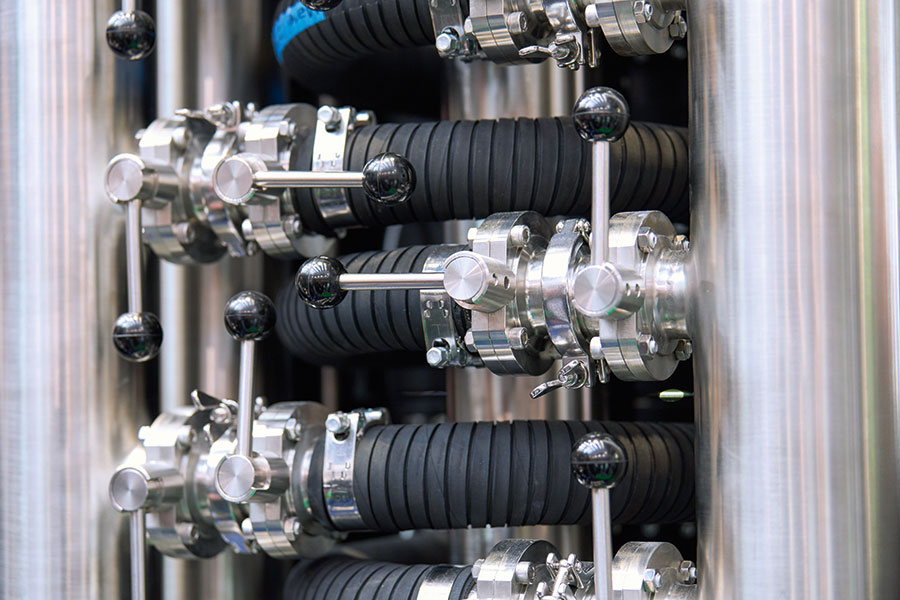

Rittal has addressed this issue by developing its Coolant Distribution Unit (CDU) in a compact rack format. Using water, this CDU delivers more than 1 MW of cooling output for single-phase direct liquid cooling of server racks. “One of our priorities was to factor in handling during operations from the outset. As far as possible, it is important that the usual processes can be used to service the system, despite the new technology,” says Michael Nicolai, Head of Rittal IT Sales in Germany. How does this work? With modularisation and the Open Rack V3 – the development of which Rittal drove forward in the Open Compute Project (OCP). Power is supplied via the rack’s standardised DC busbar. Based on this model, the server is also linked up to the central water circuit via connections in the rack. The CDU’s functional units, such as the controller unit and several coolant conveying units (CCUs), are completely modular. The benefit for servicing is that the slide-in equipment can be pulled out like servers, including while operational, i.e. in a “hot swap”.

GETTING STARTED OR SWITCHING OVER FASTER

In addition to the liquid-to-liquid version, Rittal is also planning liquid-to-air versions that do not need a water connection in the facility. “The liquid-to-liquid solution proved a real draw at trade fairs. As drivers of technology, hyperscalers in particular will use these kinds of installations in high numbers. However, we want to carry out extensive testing first,” says Nicolai. There are still many more questions to answer. What are the key things to consider in terms of the pipework for the building’s primary circuit? What changes result from the high performance density of the power distribution? How does DLC impact service during operations and ultimately the entire data centre? We draw on our experience in these areas, too – and we also know suitable suppliers,” he continues.