Text Charlotte Erdmann ––– Photography

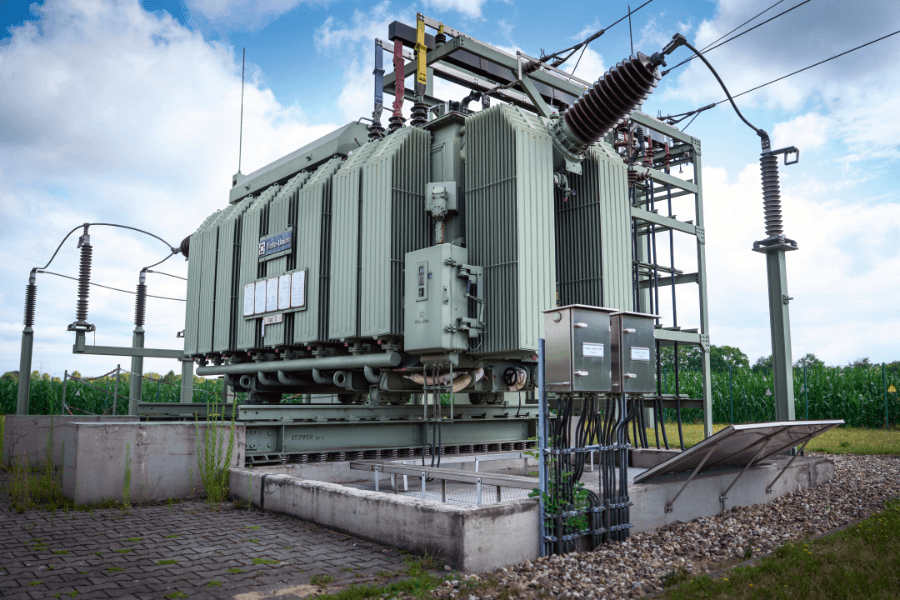

Gas and electricity aren’t magically available from nowhere in our homes. They have to be routed, distributed and transformed so they arrive when and where they are needed. Utility companies operate transformer substations, distribution substations and control stations for this purpose – some no larger than a cabinet, others the size of a house. These stations can be located in the open countryside or right in the middle of a residential area. Many are still operated using analogue controls and connected to the utility company’s grid control centre via copper lines.

Controllable = Crisis-proof

That isn’t exactly crisis-proof. In the spring of 2025, the failure of one single substation in Spain caused a nationwide blackout – with dire consequences, as reported in the media. Besides such risks, load distribution is also an important consideration, which is why Germany made this a statutory obligation at the beginning of 2024.

Load distribution only works digitally, though, and each station requires its own autonomous, intelligent control system. According to the requirements of Germany’s Federal Office for Security in Information Technology (BSI), this system must continue operating independently of the power grid for up to 72 hours. German grid operators can then respond faster in an emergency, distributing gas and electricity from various sources in a targeted way. This applies to every point in the energy network, whether substations, gas pressure regulating stations or transformer stations.

New technology in old facilities

The challenge lies in the actual implementation. “We only realised the true complexity of the digitalisation process when we considered each of our sites specifically,” explains Simon Bartoschewski, Team Leader Communication and Security Systems at ELE Verteilnetz GmbH (EVNG), the grid operator for Bottrop, Gelsenkirchen and Gladbeck. “To create a state-of-the-art communication and control system for our total of 21 sites – eleven substations and ten gas pressure regulating stations – we had to install modern technology in old industrial facilities,” he adds.

In other words, EVNG’s often decades-old medium-voltage stations had to be equipped with digital modules and sufficient battery capacity to operate for 72 hours. This was no easy undertaking, particularly since, as Bartoschewski reveals: “We wanted a holistic solution from a single source.”

Finding a solution together

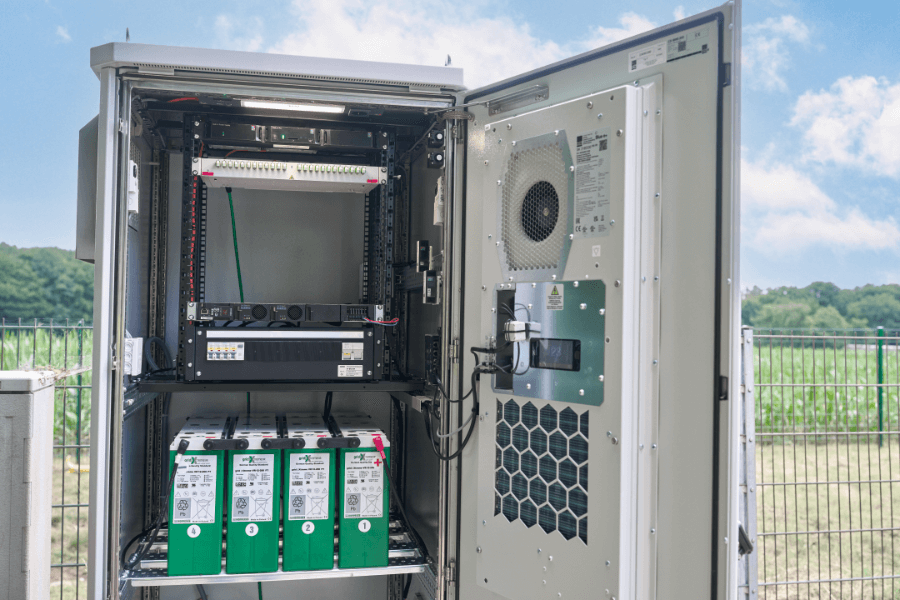

In more than one case, sites had insufficient space for 19" enclosures. Using smaller routers was not an option. “They didn’t solve the problem of the huge amount of space required for the UPS batteries, which had to last for 72 hours,” explains Bartoschewski.

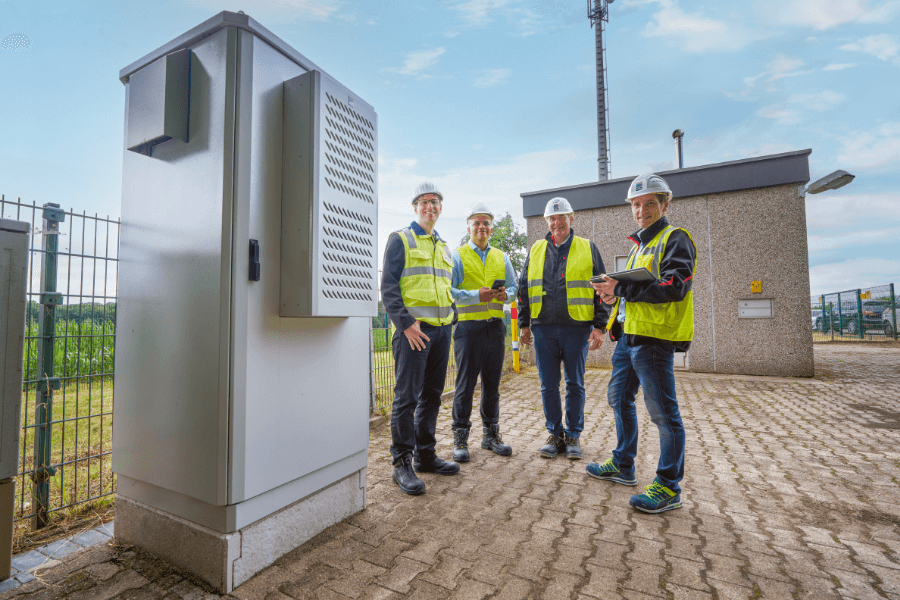

Only after an on-site visit by Bechtle and Rittal did it emerge that the solution was to be found not inside the stations, but rather outside. A software-defined wide area network (SD WAN) was a better solution for achieving digital control than copper cables. “You don’t need an external power plant or diesel generator for that, just an ingeniously configured UPS unit,” says Joachim Schwan, Team Leader Rittal Partner Management in the Key Account Management Germany department, outlining the new approach. “What’s more, our bayable and scalable climate-controlled outdoor enclosures are ideal for use outside the stations, protecting the sensitive IT technology against the elements and vandalism,” adds Stefan Hauser, System Consultant IT Infrastructure at Rittal Germany.

True teamwork produced a flexible solution based on standardised parts. “It took the joint efforts of Bechtle, Rittal and Wöhrle, together with components from Cisco, to provide EVNG with a satisfactory overall concept,” reports Ronny Jacob, Global Account Manager at the Bechtle IT System House in Rottenburg. “A single company would never have been able to come up with a solution on its own,” he adds.

Everything standardised – UPS and all

The simple and highly effective idea was to use just six variants for all 21 stations. “Incorporating the technical options of the industrial routers from Cisco, which withstand both very low and very high temperatures, solved all our major problems,” says Bartoschewski, who is clearly impressed. As for the power supply, it was incredibly complex. Rittal and its UPS partner had to carry out the relevant calculations individually for each site.

The facilities are now based on standardised UPSs. “We combined them with our modular Rittal system – for indoor or outdoor use, as required – and they can quickly be configured to create custom solutions,” reveals Schwan. Logistics ultimately also formed part of the overall solution. Rittal manufactured all the necessary IT rack solutions on a virtually turnkey basis and supplied them to EVNG’s central warehouse fully configured. From there, they were delivered to the individual stations, saving EVNG a great deal of time on site.

Intelligent networking, please!

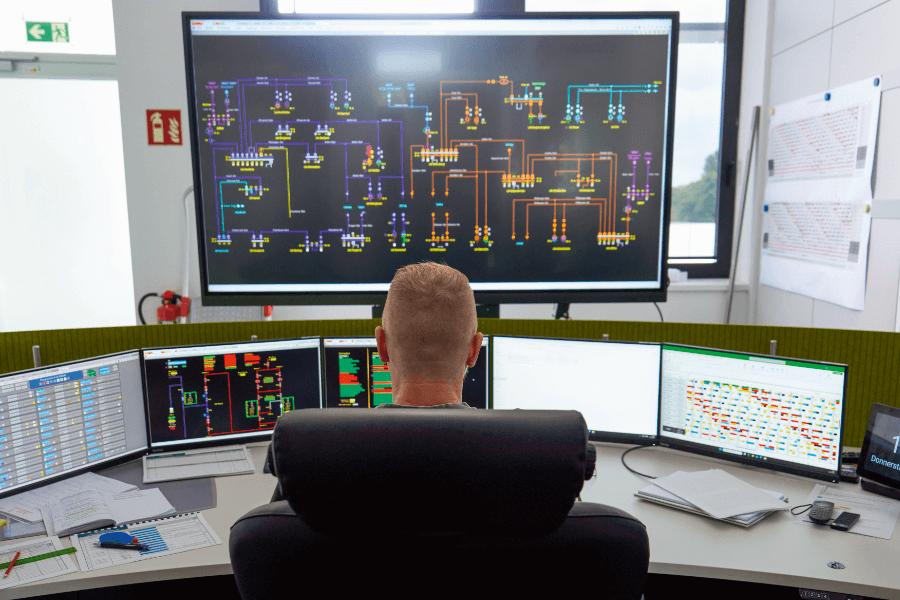

Based on this setup, the all-in-one IT racks use a cutting-edge SD WAN infrastructure to network the stations. “That means network security, bandwidths and prioritisation can be managed centrally, giving EVNG full control,” explains Jacob. Each individual station is connected directly to the control centre. If one line fails, the switch to a different one is made automatically. This is possible thanks to Cisco routers, including versions from its Rugged series in smaller stations. The result is a highly fail-safe solution that also ensures straightforward maintenance and operation. “The CMC III security monitoring system from Rittal supplies us with data such as temperature and humidity figures. That gives us certainty – not just when faults occur, but also during day-to-day operations,” says Bartoschewski.

A modular system for utilities

Vandalism protection sensors on outdoor enclosures are triggered in the event of any interference. Battery status data can also be accessed at any time. “It works for any type of connection – fibre, copper, wireless or a combination of these – thanks to COM servers that we selected specifically for this purpose,” adds Jacob. That makes the solution even more versatile.

“This 72-hour concept with six variants in a modular system is a pretty big deal for a small, local utility company like ours. It gives us a genuine unique selling point, because we have achieved something that other companies are currently still grappling with,” says Bartoschewski, describing the result of the collaboration with a sense of satisfaction. Each station gets everything it needs and can be adapted to all kinds of situations. “It’s a blueprint for other utility companies and one that we are happy to share,” he continues.

A ready-made emergency solution

Besides supplying the hardware for this project, Rittal also worked with Bechtle to create a sophisticated all-in-one system that is able to operate self-sufficiently for the necessary period thanks to a perfect emergency concept. “The collaboration always felt like a partnership of equals. We didn’t get just products, but a ready-made solution,” sums up Bartoschewski. The end result was a controllable, self-sufficient and standardised communication network for stations run by utility companies – one that continues operating for up to 72 hours in the event of a blackout – reliable, intelligent and equipped for all future uncertainties.