Text Martin Barde, Johannes Strähle, Steffen Maltzan ––– Photography

If you want to know how things are going in the switchgear manufacturing sector, you should talk to Marcel Birkenberger (46) from gefeba Elektro GmbH, a switchgear manufacturing company in Gladbeck, Germany. Birkenberger started out at the company as an apprentice – and now, 30 years later, he is in charge of production there. “It’s crazy how quickly the market is changing right now,” he says. He is referring, for example, to the soaring time and cost pressures and the growing demands on the team. He also points out that the quality of digital data is becoming more and more relevant. “gefeba is a family business that has prioritised a strong customer focus from the outset – and that’s part of what has made it successful. To continue like that, we need to keep an eye open for innovations that we can use to offer our customers tailored solutions – which are increasingly in demand – combined with short delivery times,” he explains.

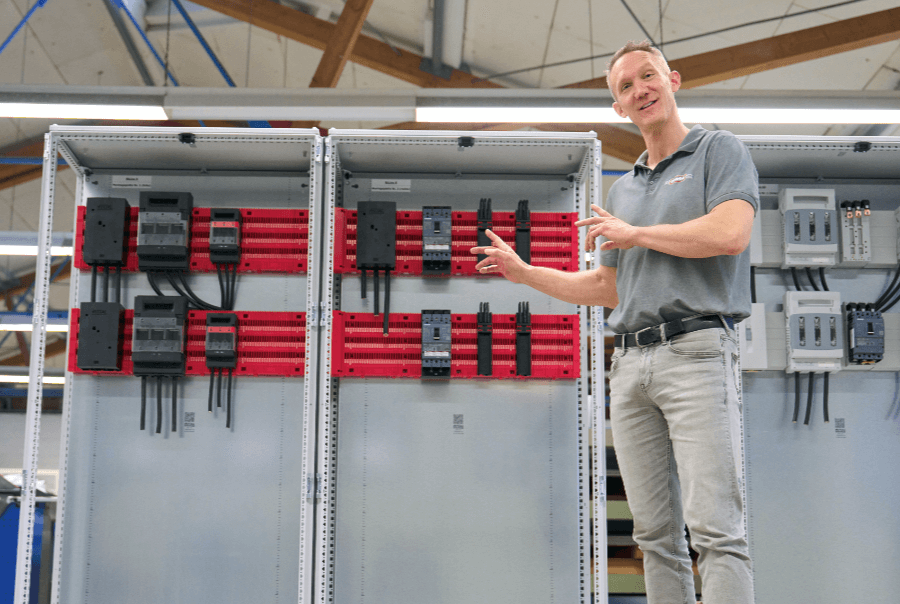

This insight is what prompted Birkenberger and his team to take part in a study commissioned by Rittal. Conducted under independent observation, this study examined how quickly the new RiLineX busbar system platform can be assembled compared to a conventional busbar system. Despite all his experience, even Birkenberger himself was astonished by the results.

A surprising innovation

There were a few surprises in store. “We were astounded that a quantum leap of this kind was even still possible in busbar technology. We laid all the components out on a table and simply gave it a go. It quickly became clear that it all works really simply,” the switchgear expert explains.

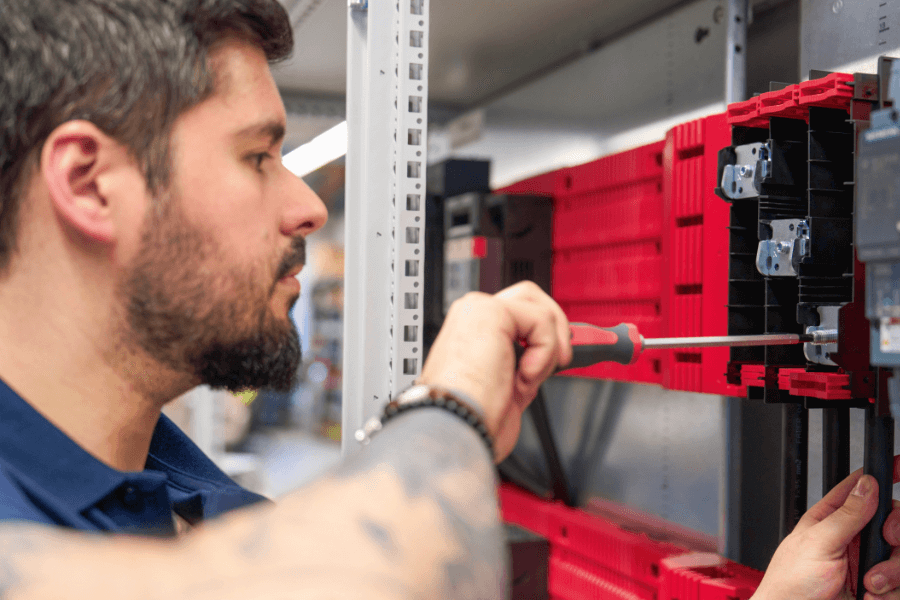

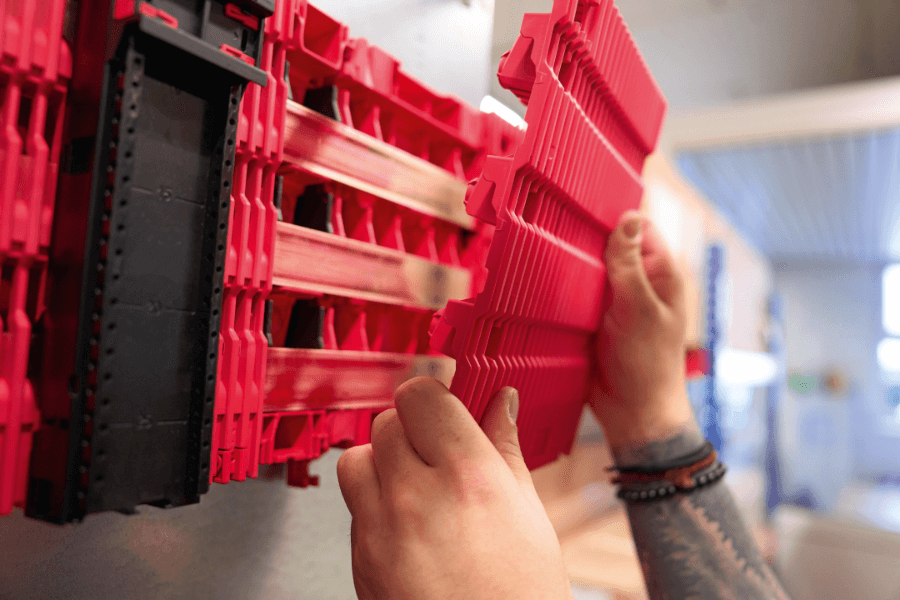

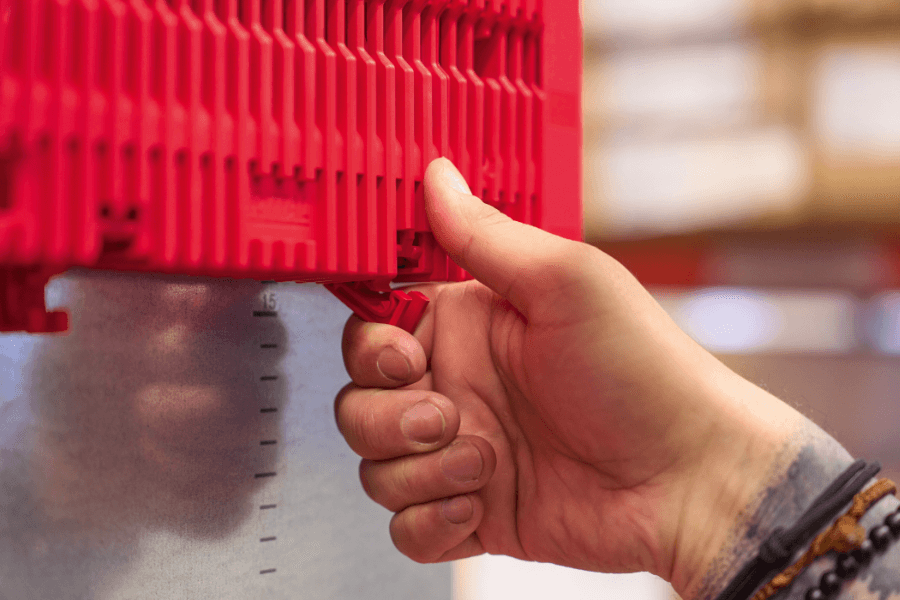

In his view, one obvious benefit of the design is that there is only one way of putting the tool-free “Click & Work” system together. The system also predetermines exactly how equipment must be installed. Assembly errors are virtually impossible. “We can now let even semiskilled staff work with the system and, given the skills shortage, that’s obviously a major advantage,” he says. He also comments that apprentices enjoy their work more when they achieve results quickly and easily. This is important, because keeping young people motivated over the long term is now much harder for employers than it was even just a few years ago.

Scientifically validated

If assembly times can be reduced, that’s always going to be of particular interest to gefeba from a cost-efficiency perspective – and this important added value offered by RiLineX has now been scientifically proven.

Conducted under the independent supervision of the Fraunhofer Institute, the study at gefeba meticulously worked out the amount of time needed to carry out various assembly steps, comparing the new RiLineX with the conventional RiLine60. Various installation options were also compared, such as completely manual assembly and machine-assisted assembly, where an automated CNC milling machine drills the holes in the mounting plate. Similarly, the options available with RiLineX – installing a preassembled complete board or installing modular components individually – were also compared. “For the study, we deliberately identified work steps that are essential for almost all our projects. In that respect, what we have done here isn’t just theory – instead, it’s a realistic representation of many switchgear manufacturers’ day-to-day work,” Birkenberger explains. Volker Schmidt, who is in charge of RiLineX product management at Rittal, adds: “To ensure the study was relevant, it was important to us to select a company staffed by expert professionals who have lots of experience of using the old systems efficiently. gefeba fit the bill perfectly.”

Results of the study

The results couldn’t have been clearer. The measured increases in speed were so substantial that they exceeded even estimates from Rittal by a considerable margin. On average, the professionals at gefeba needed 75 percent less time to put together the preassembled complete board manually. This time saving even rose to 80 percent when using CNC technology to assist with assembly. The main reason for this is that RiLineX does not use individual supports that need to be arranged one by one to protect against short circuits. The bars are securely contained in the board, and components can be installed anywhere on them. Another advantage of the complete board is that busbars and contact hazard protection do not need to be cut to size. The boards are supplied ready to use, so it’s simply a case of unpacking them and screwing them in place. And that’s it.

As the modular boards offer greater flexibility, there’s a little extra work involved, but the amount of time saved compared to RiLine60 is still significant – 60 percent in the case of manual assembly and 55 percent in the case of machine-assisted assembly.

Whichever construction method is used, the RiLineX design is also a standout success when it comes to baying additional enclosures. To connect two separate busbar systems retrospectively, the gefeba experts took over 21 minutes with RiLine60, compared to under three and a half minutes with RiLineX. “From our perspective, this is one of the key ways in which RiLineX offers added value,” says Birkenberger, referring to this time saving. “It means less work for us when we’re expanding the power distribution system in a manufacturing company, for example. Even more importantly, it means a much shorter interruption to our customer’s production operations and, depending on the production environment, that can save the plant operator a huge amount of money,” he explains.

Installing accessories is also so much simpler in the case of RiLineX – and this has a similarly positive impact. The study recorded the time taken to install connection adaptors with and without electrical feed-through, fuse-switch disconnectors, circuit breakers and OM adaptors – and some of the results revealed huge increases in speed with the new busbar solution. For example, compared to RiLine60, installing an OM adaptor was 85 percent faster.

Cutting shifts in half

“It’s absolutely staggering that we can save so much time simply by using the right busbar system,” says Birkenberger, commenting on the study results. “When I convert these percentages into working time, the results mean I can essentially save half a working shift for each enclosure. That’s a huge gain in efficiency.” However, what this experienced switchgear professional considers at least as important – if not more so – is that his customers will also benefit from the new Rittal solution. “The study has shown pretty clearly that RiLineX is one of those innovations that will enable us to respond to the changed market requirements in a really practical way. We ourselves will become more efficient, and our customers will get a solution that is very easy to handle and can be extended flexibly. It’s a win-win situation,” he says. He’s also a fan of the system’s red colour. “I really like the fact that the boards come in that unusually vibrant colour. Even from a distance, you can clearly see that the very latest technology has been installed here!”