Text Birgit Hagelschuer ––– Photography

Mechanical engineering companies face a delicate balancing act. Customers increasingly require one-of-a-kind, made-to-measure machinery and equipment. Delivery deadlines are also tight. Further challenges include the growing competition from low-wage countries and the worsening skills shortage. All this makes efficiency the order of the day.

That applies to machine planning, the enclosure and, last but not least, the connection between machine and enclosure – an aspect that clearly requires some attention. After all, cables are now a significant cost factor. If they are too short, too long or – worse still – incorrectly planned, the outlay increases. The standard mechanical engineering approach to date is based on trial and error, which results in a correspondingly high risk of errors. If cable planning is done by eye, things can certainly get tricky.

If a cable is too long, for instance, it is typically tucked away or hidden in coils under the enclosure or machine. The resulting bending radii and requirements relating to electromagnetic compatibility (EMC) are often not factored in. Interfering signals can lead to malfunctions and lengthy commissioning processes. Besides being difficult to pinpoint, they are also extremely time-consuming and costly.

EASIER WITH A DIGITAL TWIN

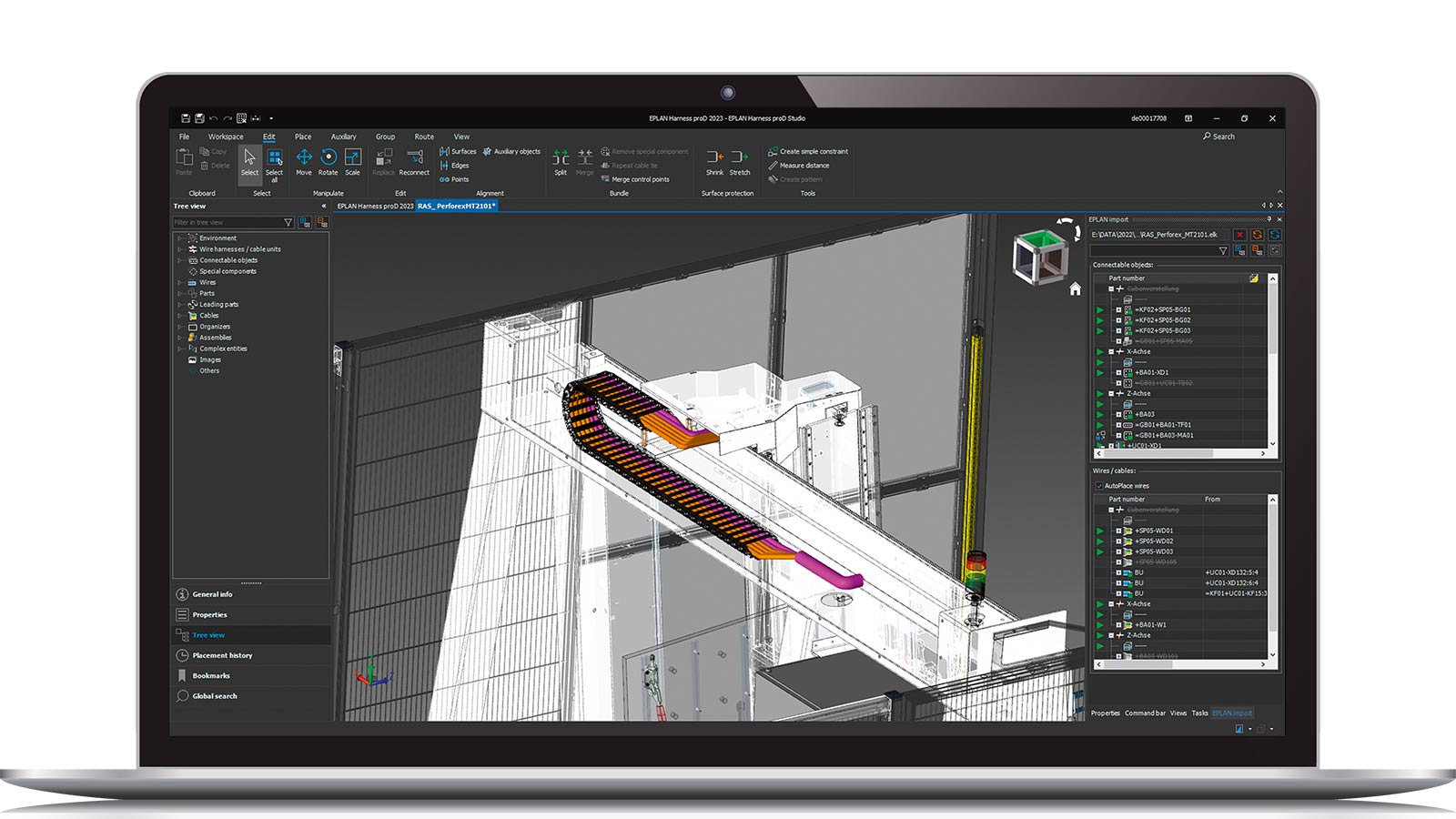

Wouldn’t it be better to know the exact cable lengths in advance – especially with a view to ensuring fast, error-free Plug & Play installation using the kind of pre-assembled cables that are now standard? It certainly would, but that requires appropriate tools and data, ideally based on a digital twin. The 3D software Eplan Harness proD can now be used to create just such a digital twin that serves as a basis for machine cabling. The cable planning process couldn’t be simpler. Design engineers use Eplan Electric P8 to plan the necessary cables in the circuit diagram (schematic), while also specifying the articles required for cabling inside the machine “along the way”, as it were.

NO CHANCE OF ERRORS!

These engineers simply link the Eplan project and the 3D enclosure layout in Eplan Harness proD, where the 3D geometry of the machine or system can also be imported. Based on the information from Eplan, the equipment is positioned in the 3D environment, and the design engineers obtain a digital twin of the cabling in its entirety. This brings the electrical engineering and mechanical worlds closer together. Everyone is using the same data as a basis, but they remain flexible in their own particular working environment.

With this integrative process, things become evident much sooner that would otherwise only be revealed at the physical prototype stage when using the traditional working method. Any changes – when creating a prototype, for instance – can be implemented on the PC with just a few clicks of the mouse. A real-life counterpart is no longer required in production or the workshop.