Text Dr. Jörg Lantzsch ––– Photography

Different systems for electrical and construction planning, printed lists and using USB sticks to transfer data to machines – end-to-end data availability was sadly lacking in standard practices at Müller Schaltanlagen up until 2020. “Our previous solution had been created over a period of many years and had numerous drawbacks,” admits Lukas Ortmann, who is responsible for CAD, project and production planning at the company.

Many businesses in the sector have similar outdated solutions. Production planning is the real bottleneck. In panel building and switchgear manufacturing, this step is often highly complex. Without an appropriate platform, companies are forced to utilise the interfaces of the individual machines during planning, which means more time is required for production planning and manufacturing. Moreover, panel building and switchgear manufacturing involve a whole host of steps that need to be coordinated – from milling and laser machining to wire processing and wiring.

RETHINKING PROCESSES

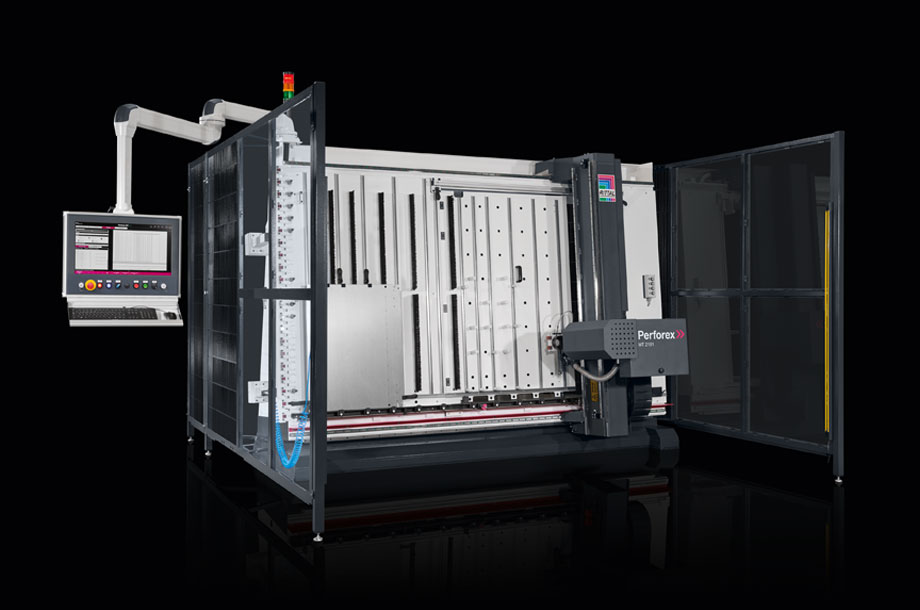

Extensive automation of both job planning and manufacturing is a must if companies are to meet customer pressure. As Ortmann explains, Müller Schaltanlagen is no exception: “In early 2021, when we were about to invest in a new Perforex MT machining centre, we also had a complete rethink when it came to our construction and production planning.” The company has since been using the RiPanel Processing Center from Rittal, a job management tool that acts as a hub between engineering and manufacturing.

SMOOTHING THE PATH TO THE MACHINE JOB

The software takes the design data from the engineering stage, registers parameters such as the quantity and target date, and then converts the data into machine jobs. Consequently, machines such as the Perforex milling centre know exactly which job is next. The RiPanel Processing Center can also plan and carry out the further steps.

The software currently supports the new Perforex MT Milling Terminal and the Secarex cutting centre, but the ultimate plan is for all Rittal Automation Systems machines to be connected.

FEWER ERRORS

The RiPanel Processing Center digitalizes and combines the three traditional manufacturing steps. At the engineering stage, the Müller Schaltanlagen planning team uses Eplan Pro Panel software to create the digital twin. The data can then be fed via direct interfaces into the job management tool, where the project file containing all the machining information is split into the various machining steps and forwarded to the relevant process steps in production.

Per Klick vom Engineering zum Maschinenauftrag

Engineering

Im Zusammenspiel von Eplan Engineering-Tools mit Rittal Konfiguration entsteht der digitale Zwilling, der alle produktionsrelevanten Daten enthält.

Arbeitsvorbereitung

Die einfache, zentrale Planung von Ressourcen und Produktionsaufträgen für die Fertigung erfolgt über das RiPanel Processing Center mit moderner Auftragsverwaltung und Layout-Tool.

Fertigung

Die konsequente Nutzung der digitalen Daten bei mechanischer Bearbeitung und Verdrahtung bietet erhebliche Vorteile und erspart die Programmierung an der Maschine.

The actual workstations use this data for efficient job processing. “The resulting end-to-end data management – from electrical and construction planning to production planning and manufacturing is much more efficient and also prevents the errors that could easily occur in the past due to the numerous manual steps,” says Ortmann, who is highly satisfied with the new solution.

ALWAYS KNOWING WHAT’S HAPPENING

The new development is the first to support intelligent job management, while manufacturing benefits from end-to-end data management. “Eplan Pro Panel provides us with a text-based description of the digital twin, which is then forwarded to the RiPanel Processing Center,” explains Rittal product specialist, Thorsten Freytag. The AML file the system uses has an open data format that is sent to the machines.

To ensure users maintain a constant overview of the manufacturing process, the machines use a status feedback function to keep the RiPanel Processing Center up to date on the manufacturing status, meaning that resources can be utilised and distributed efficiently. As a web-based tool, the “job manager” can be used anywhere, which gives workshop managers a high level of flexibility for easy and efficient job management.

CLOUD SOLUTION IMPROVES WORKFLOW

Straightforward communication between engineering, production planning and manufacturing must be ensured to make the entire manufacturing process transparent throughout all the individual steps. That is why the RiPanel Processing Center is designed as a cloud solution. The various machines installed are logged in the Eplan Cloud, together with their respective functions and features.

“Following construction planning, we use the RiPanel Processing Center to transfer the finished project via the Eplan Cloud to the Perforex MT Milling Terminal,” explains Ortmann. “The machine operator then immediately sees the job and can clamp the appropriate part in place and start machining with a single click. This workflow provides a huge boost to efficiency,” he adds. The status feedback function keeps users up to date on the manufacturing status. “We can give the planner and workshop manager a complete overview of resources and thus also achieve a corresponding increase in efficiency,” says Freytag.

The RiPanel Processing Center is delivered as a basic package, together with the relevant machines, which means it costs users nothing. As a result, panel builders and switchgear manufacturers have an easy and cost-effective solution for the digital mapping and automation of their manufacturing processes. This cuts throughput times, reduces the number of manufacturing errors and saves on costs. “We are completely satisfied with our new solution,” confirms Franco Müller, Managing Director of Müller Schaltanlagen.