Text Birgit Hagelschuer ––– Photography

Interdisciplinary configuration is now really taking off in mechanical and plant engineering to meet the demand for customised products at a reasonable cost. That calls for a high level of automation, together with extensive integration of all processes – including engineering-to-order. In large parts of the industry, however, this is not yet standard practice for configurable products that involve engineering work.

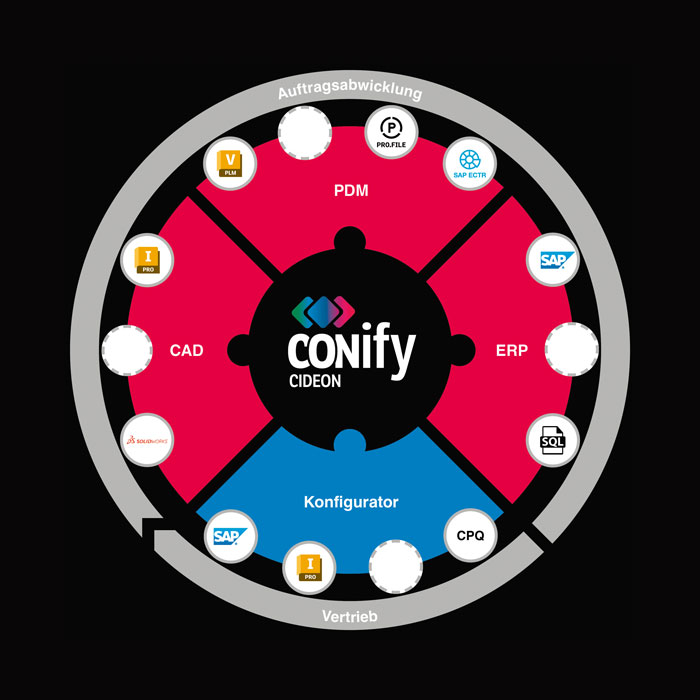

Cideon has now developed the ideal solution in the shape of Cideon Conify. It automatically generates the configured product – the digital product twin – as a CAD data set and then saves it in a PDM-compliant format. The engineering-to-order team is thus able to incorporate customer-specific modifications with the minimum of additional outlay. This provides their order processing and production colleagues with clear and consistent documentation, bills of materials and work schedules. The result is a standardised, digital process that extends from creating orders all the way through to delivery with the maximum level of automation.

USING CONFIGURATION TO BOOST ADDED VALUE

The approach to processing products with multiple variants must be consistent throughout the entire value chain – from product development and sales through to engineering-to-order and delivery. Data management continuity – without any deviation or redundancy – is key during each of the sub-processes involved. The product development team already lays the foundation with well thought-out product standardisation and modularisation as well as associated mapping in product configurators and appropriate CAD models. This is the starting point for all subsequent steps.

The sales team can then use the relevant data and systems to prepare competitive quotations enhanced by visualisations, drawings and CAD models. Cideon Conify automatically generates CAD-neutral product data on the basis of the available parametric CAD data, normally in the form of a simplified overview. If an order is placed, this data will become more detailed. When creating the order, the parametric data can be used to generate detailed product assemblies, drawings and production documentation. This enables complete part masters and bills of materials to be created for any particular variant, while also ensuring the accurate reuse of historical components and assemblies.

If, as is often the case, modifications are required for specific orders, the engineering-to-order team will be able to locate the CAD data pregenerated by Cideon Conify in the PDM/PLM system and can focus on the changes necessary. This step in the process creates further bill of materials and article data that is used in company processes via standard interfaces – as a basis for further value creation right up to the point of delivery.

OPEN FOR INTEGRATION

Cideon consultants help businesses create an end-to-end configuration process. A configuration discovery workshop identifies potential for optimisation, and initial specific implementation plans can then be developed based on a target vision derived from a realistic demo model. This clearly defines how to create a lean pro-cess for products with multiple variants.

The modular concept of Cideon Conify can be extended and various systems can be integrated. Sales configurators such as SAP and FDU (Autodesk) are currently supported, as are the CAD systems Solid-Works from Dassault Systèmes and Autodesk Inventor. When it comes to PDM, the focus is on Autodesk Vault and SAP ECTR, but other systems can also be connected or planned to be connected.

IN A NUTSHELL

Cideon Conify is taking configuration processes to a whole „new level“. Project lead times – from customer inquiry to order – are much shorter, the quality of quotations is better and the number of recurring tasks can be reduced from the outset.