A data set in the Eplan Data Portal is almost a digital twin for a component and contains all the information required for the subsequent process, from the automated production of the mounting plate with drilled holes, threads and cut-outs through to wiring. The Data Portal holds 2.5 million data sets for components from 400 manufacturers, meaning there are no restrictions on utilising this data. “During the study even just using the Data Portal resulted in a seven-hour time saving compared to using STEP data in the layout,” points out Schüler, highlighting the benefits. Once all the components have been placed, the software can place the wiring on a fully automated basis. Based on the wire diameter, it is possible to calculate how full the cable conduits will be. Terminals and components can be transferred to programs for preparing processes and to ERP systems for placing orders.

DATA THAT IS FIT FOR PRODUCTION

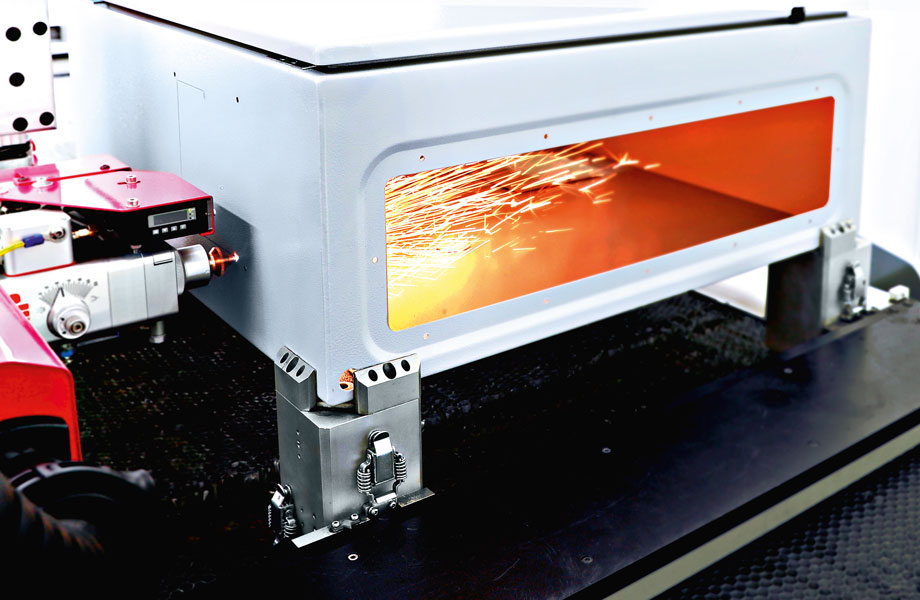

In a project, all engineering data derived from the digital twin can be transferred to the order management tool, RiPanel Processing Center. The jobs are then assigned to the different process steps. For example, the data for mechanical machining is transferred to the “Perforex Milling Terminal” for milling or to the “Perforex LC3030 3D laser” for laser processing. The data for fully automatic wire processing is sent to the new “Wire Terminal WT C”, where the wires are cut to length, printed, and the wire ends are treated with end ferrules. In addition, it will be possible to send the information for the processing of busbars to the machines of the company Ehrt, which now also belongs to Rittal Automation Systems. With the solutions for automated processing for cutting, punching and bending the copper bars, production processes in plant engineering can be further optimised.

DIGITAL AIDS

The next production step accounts for the biggest share of the manual work – mounting plate assembly and wiring. All components such as C rails and cable conduits are screwed into the prepared assembly holes and the wires are connected and laid. Wiring is one of the most time-consuming, error-prone and complex steps, and one that Rittal and Eplan are optimising and simplifying with various solutions.

A step-by-step guide such as Smart Wiring is a great help. Staff are shown each wire individually – in 3D, if desired. Thus, the wiring is entirely system- managed and is additionally supported by the sequentially arranged or requested wires from the Wire Terminal: From the first connection point on the terminal strip, through the visualisation of the routing path in the cable duct, to the correct connection to the electrical component. “Errors are spotted faster, progress is documented precisely and conduits are filled evenly, just as the software has calculated during the engineering process. As a result, faulty wire connections are almost systematically eliminated so that this work can, in theory, also be carried out by non-electricians,” explains Tim Kramer, head of Product Management & Product Marketing at Rittal Automation Systems.

AUTOMATED WIRE “SHOOTING”

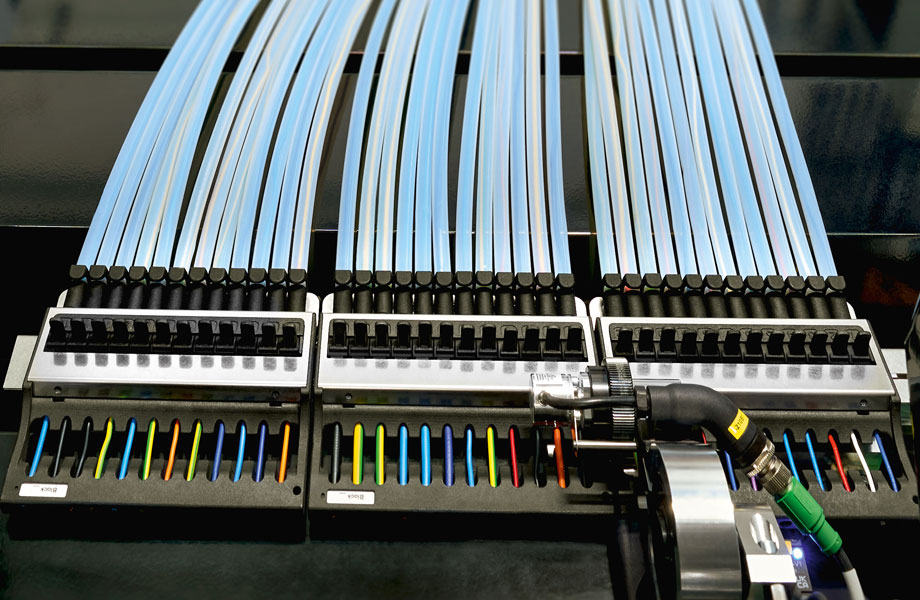

Pre-prepared wires offer additional certainty because they are produced and sequentially arranged in how they will be processed later. Rittal has appropriate solutions for this, too, with machinery using data from Eplan to prepare wires by cutting them to the length specified in Eplan, attaching end ferrules and labelling them. The wires are stored in a rail system or as a bundle that has been arranged in the correct sequence. Smart Wiring then guides workers through the process of installing the wires in the sequence produced by the wire processing machine. “We’re now going a step further with the new Wire Terminal WT C. The system doesn’t just prepare the wires, it also ‘shoots’ them to the workstations, on a virtually just-in-time basis,” says Kramer. To do that, the system uses Teflon hoses that run from the machine all the way to each workstation, covering distances of up to 80 metres. The prepared wires are “blasted” to the relevant workstation with compressed air, and the WT C can serve several workstations in parallel. A ring sensor at each workstation registers when a member of staff has removed a wire, which results in the next wire being supplied to the workstation via Smart Wiring.

“Thanks to this kind of assistance and automation, staff working on wiring tasks don’t need as much specialist expertise, which means valuable specialists can be put to work where their know-how is really needed,“ says Kramer. And adds: “Such as in testing or engineering.” As a result, automation doesn’t just make work easier, it can also help with tackling the current skills shortage.