Text Birgit Hagelschuer ––– Photography

Available since July 1, Cideon Enify is a new software solution that supports efficient new service concepts for small and medium-sized mechanical and plant engineering companies. Cideon developed this solution with a clear goal in mind. It aims to rectify faults and defects affecting the live operation of a machine or plant on the first attempt and to do so worldwide and, wherever possible, digitally – without a service engineer having to travel anywhere.

“This software helps mechanical engineering companies that operate worldwide get around all the current travel restrictions on the global market. At the same time, it fosters closer links between machine suppliers and operators, even when they are in different countries,” sums up Stephan Kranz, Head of Special Projects at Cideon. By developing Enify, Cideon is also looking to make its customers more competitive, as it can be used to create completely new after-sales service concepts.

REAL-TIME VIDEO TRANSMISSION CREATES CLARITY

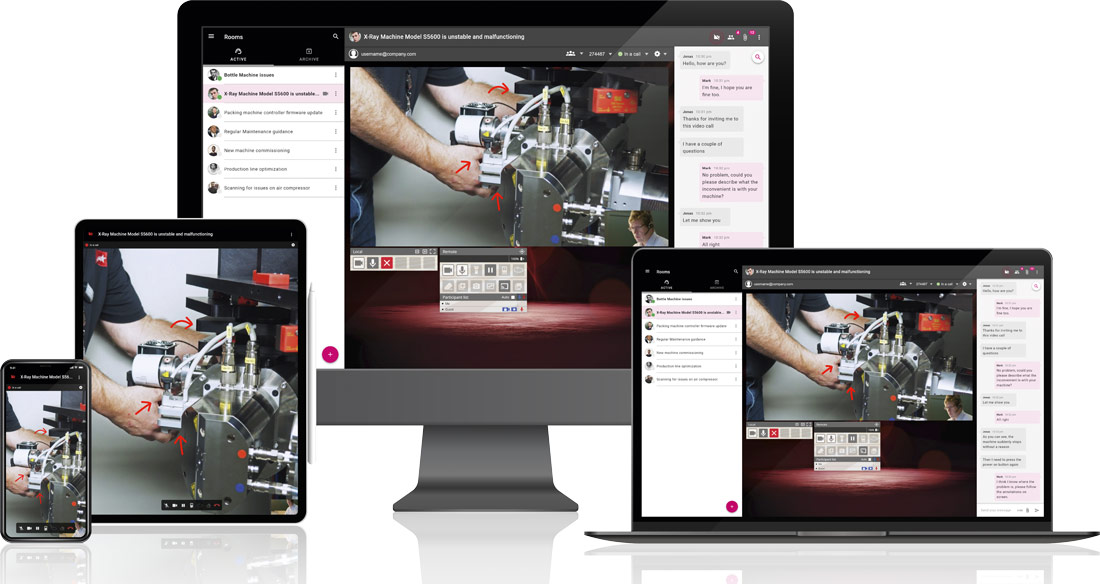

The first step is to set up the app as a messenger service with video function. Eplan, a sister company of Cideon, provides the technical basis for this with its Eplan cloud, which takes care of user management. Images and videos of a machine or system can be shared on any end device – from smartphones and tablet computers to PCs – without having to install anything. What makes this app so special is that key areas of the system can be marked and labelled using a live pointer based on AR technology.

Thanks to the drawing function, a service engineer can give operators instructions in real time, telling them how to repair or maintain the machine. At the same time, live transmission helps prevent ambiguities, especially if there is a language barrier. A further advantage is that the cloud automatically stores all service events, which means everything is documented directly.

NEXT STEP – LINKING ERP AND CAD

Further functions are systematically being added to the new software solution. Cideon is already planning to link CAD systems and ERP solutions to Enify soon. It will then be possible to compare parts lists in systems such as SAP or connect shop systems, for example. The experts at Cideon are also taking a ground-breaking development step by actively inviting existing and potential customers to act as pilot customers and take on a practical role in influencing how the solution evolves. The ultimate aim is to create a software solution that precisely reflects SMEs’ current and future practical requirements. It almost goes without saying that the concept incorporates cutting-edge technologies such as augmented reality and smart glasses.

CONCLUSION

As Kranz explains: “Cideon Enify is a valuable tool that helps forge closer links between mechanical and plant engineering companies and their end customers. Using the software is like pressing the alarm in a lift. We’re giving companies the option to coordinate live, digitally and in real time in the event of a fault.”