Text Birgit Hagelschuer, Hans Robert Koch ––– Photography

O ur society and the entire energy industry are undergoing a transformation – becoming an all-electric society. Fossil primary energy sources such as petrol, diesel and natural gas are set to be replaced by electrical power. This will mean a huge increase in the demand for electricity, and grids will need to become much more flexible. However, it will be impossible to expand and convert the necessary number of distribution and transformer substations using the current design engineering and production methods.

STANDARDISATION AND INDUSTRIALISATION ARE VITAL

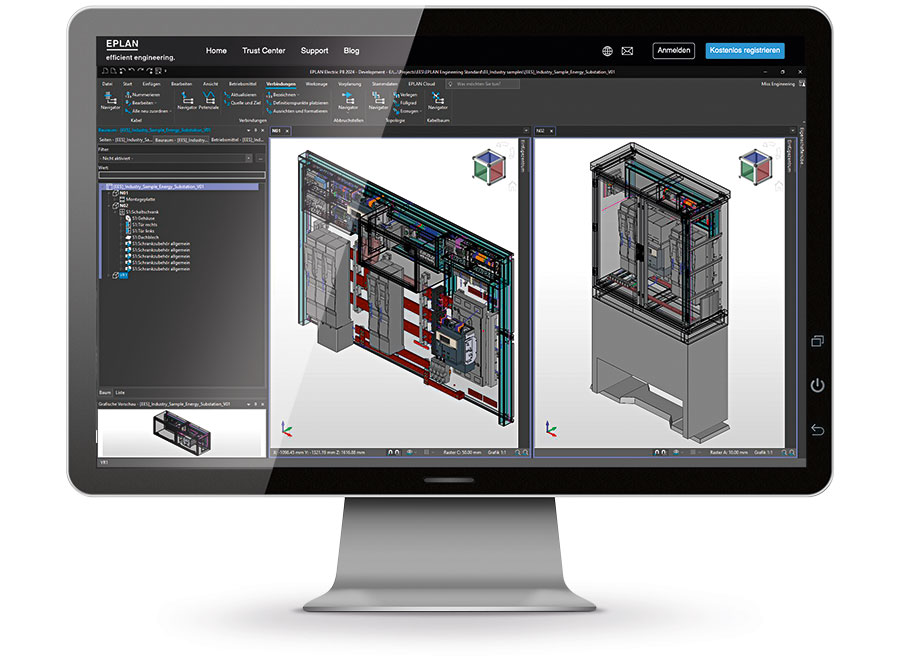

How can this demand be met? Industry, and the mechanical engineering sector in particular, are showing us how. Machinery is normally based on standardised series that can be adapted for each specific order. Standardising the electrical engineering of this machinery starts at the design / project planning stage. Design engineers either use a master project that they modify for each order-specific project or – better still – work with a wiring plan (schematic) configurator such as Eplan eBuild. All they need to do when using this configurator is click the relevant functions, key data, variants and options. Wiring plans, parts lists and other documents are then generated on an automated basis.

“This sophisticated IT-supported and partially automated electrical engineering would be inconceivable without Eplan,” says Gerrit Helms from the Vertical Market Management Energy team at Eplan. “The associated digital continuity in particular offers companies fresh potential,” he adds. This continuity applies both horizontally across the various stages of project planning – from preliminary planning using Eplan Preplanning to commissioning and maintenance – and vertically across individual disciplines, all the way through to the supplier for tasks such as cable processing.

BENEFITS OF DIGITAL CONTINUITY

This kind of computer-aided engineering (CAE) is beneficial for operators of power grids and decentralised energy systems who are looking to speed up their processes using digitalisation and (semi-) automation. It lays the foundation for standardisation and digital continuity throughout the entire construction and manufacturing process. Suppliers of the protection and control technology modules, for instance, can continue to work seamlessly with the documentation from project planning and add their detailed engineering to the existing project. This significantly speeds up and rationalises the design engineering and manufacturing of these modules. According to Jan Oliver Kammesheidt from the Global Vertical Market Management Energy team at Eplan, operators can take this digitalisation and automation step without any kind of risk. “Numerous suppliers are already using standardised and automated electrical engineering with Eplan and are familiar with it from other industrial projects,” he explains, adding that many manufacturers also include documentation in Eplan as standard when delivering switchgear and transformers. “We thus ultimately complete the perfect full circle, ensuring digital continuity in the documentation used during the subsequent operation of the systems,” he says.