Text Barbara Sawka ––– Photography

Watches, cheese, chocolate – Switzerland is famous for these products the world over. And although panel building and switchgear might not be considered a typically Swiss product, the country is home to lots of innovative companies in this field. One of those companies is W. Althaus AG, whose motto – and the secret to its success – is “Leading in Automation”. When it comes to automation, W. Althaus AG is ahead of its time and has forged something of a pioneering role in Switzerland. “Six or seven years ago, automation didn’t have such a high profile. Manufacturers also had to learn how to design their products so they could be automated,” recalls Marco Schneider, CEO of the company, which is based in the canton of Bern and bears the name of its founder, Walter Althaus. In the meantime, as Schneider himself admits, the topic has certainly come to the fore – and not just in Switzerland.

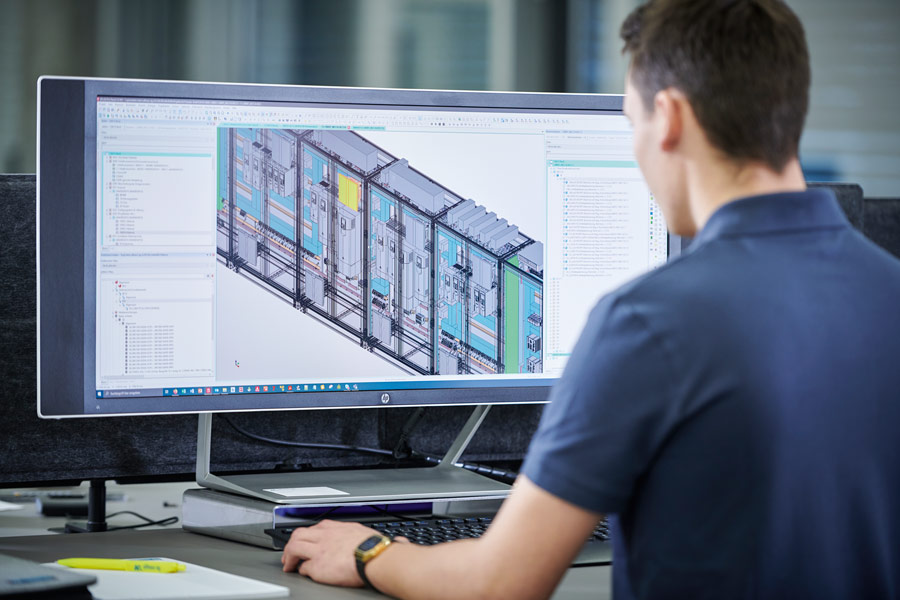

This has resulted in new challenges. Customers want to operate in a more consistent way, from ordering through to commissioning. Markets are becoming more volatile and that is demanding greater flexibility. Schneider is certain that automation can help: “You can automate or semi-automate certain steps and free up specialists to focus on specialised tasks.” This has long since been the way things are done at W. Althaus. The company identifies with the topics of automation and digitalization – “I think it’s in our DNA,” says Schneider. That is why it has been using Perforex machining centres from Rittal to machine enclosure panels for many years. Panels measuring up to 2450 x 1600 mm can be clamped in place in these machines, which can process all the materials commonly used in switchgear, such as steel, stainless steel, aluminium, copper and even plastic. The quality of the cut-outs is excellent, and the average machining time on the Perforex is only between 15 and 20 minutes per part.

THE KEY TO DRIVING DOWN COSTS

The complex automation task of cutting top-hat rails to size and fitting and labelling terminals is taken care of at W. Althaus AG by the Athex terminal block assembly centre. The machine is an in-house development from the innovation powerhouse that is W. Althaus AG. Like the Perforex, it processes data from Eplan Pro Panel, a software package for planning the construction of enclosures in 3D. The support rails are automatically measured from the buffer store and cut to size before a needle engraver is then used to label the underside with text, a QR code, etc. for order picking and project planning. After that, a gripper system fits the terminals directly to the terminal strip. The company’s Secarex cutting centre also obtains data from Eplan Pro Panel. It quickly, precisely and safely cuts wiring ducts to length – including covers and support rails. The integrated label printer takes care of projectspecific labelling. Optimised cutting waste and an accelerated overall process ultimately result in lower costs, too.

THE “WIRING” CHALLENGE

Switchgear manufacturers still need to spend a lot of time on wiring, and this is where Schneider believes the biggest potential savings now lie. Althaus is currently working with Rittal to develop automation solutions for enclosure wiring that are focused on the mounting plate. The biggest challenge is the complexity of the wiring, which is not limited solely to the mounting plate – there are connections to the doors, side panels, roofs and bases in the enclosure, and to bayed enclosures, too. The situation is further complicated by the fact that technical standards vary depending on the country where the enclosure is to be used. The concept of automated wiring envisages, among other things, automatically wiring up strands that have been preprepared on the Rittal Wire Terminal.

“Our solution is based on a collaborative approach. In other words, we don’t want to make everything 100 per cent fully automated. The steps that can be automated will be taken care of using technology and the rest will be down to a member of staff,” explains Schneider.

THE ANATOMY OF DATA

Another area where added efficiency can be achieved is in engineering – but additional gains rely on good data. As far as Schneider is concerned, that is the key to achieving consistency throughout processes, and he offers an interesting analogy: “It’s a bit like the human body. You have to understand its anatomy – how is the body constructed, how does it work, what correlations and interdependencies are there? Once doctors know all that, they can suggest appropriate treatments. It’s a similar situation when it comes to data. It is the basis for automated and digitalized downstream processing.”

The Eplan Data Portal provides this basis. Only recently, a whole host of users were brought on board to help develop a data standard. Initial results have already been incorporated into the portal. Schneider sees this as a step in the right direction: “We need component data from all manufacturers to be standardised and unified. The Data Portal provides the place where data from various manufacturers can be pooled and made suitable for use via the engineering tools from Eplan.” However, Schneider is clear that data must satisfy the required high quality standards – just as the data provided by Rittal does.

Recent years have certainly seen much faster growth in the number of companies coming to realise the opportunities offered by digitalization. Schneider is confident that this is where the future lies: “I think cloud-based solutions are most certainly an opportunity for companies to work closely together on an overarching basis. Eplan eVIEW is a first step in the right direction. It gives everyone involved access to project data – from engineering, production and assembly through to service and maintenance.” Through its free software, the Eplan ePulse cloud environment facilitates structured cooperation with colleagues, customers and other project participants.

„SMART ENGINEERING & PRODUCTION“

The philosophy at W. Althaus AG is not to wait for the market to reveal what manufacturers and companies are developing, but instead to take an active role in driving forward innovation. A key success factor in this is working with strong partners and pursuing development collaborations, not just with Rittal and Eplan, but with Phoenix Contact, too. “Our cooperation is very intensive. We keep in regular contact with all three – discussing developments and optimising processes. We put our heads together to see what the future might hold,” says Schneider, describing what it is like working with his partners. The three companies have come together to form a technology network named “Smart Engineering and Production”, which suits the approach at W. Althaus AG very well. It all started five years ago and, since then, these ideas have transformed into concrete product innovations. The configurators, engineering platforms, automation solutions for production and digital assistance systems work together hand in hand.

Article data is described in a standardised and consistent way for use in the engineering, materials management and production processes involved in enclosure manufacturing. In this way, it helps deliver an entirely digitalized process based on the “single source of truth” principle. The network has also come together to develop standards such as ECLASS for the digital description of articles and article data.

ECLASS has since established itself and, combined with Automation ML, is playing an important part in the cross-system provision of data in engineering, configuration and production. Schneider is very positive about the technology network comprising Rittal, Eplan and Phoenix Contact: “Cooperation is vitally important, but not just on the manufacturer side. You also need to identify with users and nurture interaction and contact so you can establish what the customer actually needs.”