Text Ralf Steck ––– Photography

It all started at the opening ceremony of the Rittal Application Center (RAC) in Houston. On a guided tour by Moises Abreu, who is responsible for copper busbar machining solutions at the RAC, Greg Andrews stopped spellbound in front of the punching and bending machines that had just been delivered from Rittal Automation Systems. “They were exactly what I’d been looking for,” recalls Andrews. “I immediately wanted to buy the machines. I knew they would deliver an incredible boost to my business!” he adds. Abreu was initially less enthusiastic, because he knew the machines at the RAC aren’t supposed to be for sale. “We found a solution in the end, though,” he reveals.

CUSTOMERS TEST APPLICATIONS

The RACs are not just showrooms for Rittal enclosures and production equipment. Almost like a training centre, they give customers a chance to work with specialists from Eplan and Rittal to develop, optimise and implement their own application scenarios. The RAC equipment is also used for small and medium-sized series. Ideally, this means customers can develop their processes and have the first parts produced before they purchase a machine (complete with a verified process) and start series production at their own production plant.

A Business Development Manager in the Value Chain Team at Rittal North America LLC since August 2023, Abreu is building up the RAC in Houston. He previously worked in Germany, at Ehrt Maschinenbau in Rheinbreitbach, where the punching and bending machines Andrews was so keen to get his hands on are developed and built. Ehrt has been part of Rittal Automation Systems since 2022. Its punching and bending machines and its material feeding systems can machine busbars for use in enclosure manufacturing that are capable of transferring high currents.

BUSBARS HIGHLY SOUGHT AFTER

The US busbar market has been growing extremely fast for a number of years. There are two good reasons for this. Firstly, busbars are needed for the power supply of data centres, which are springing up everywhere. Secondly, the US government triggered a modernisation wave in 2021 with its nationwide Infrastructure Investment and Jobs Act, providing 1.2 trillion dollars of funding. This is leading many companies and public institutions to modernise their ageing electrical installations. As in Europe, thick enclosure cables are being replaced by busbar systems to distribute high currents. However, production capacities in the USA have so far been inadequate. According to Andrews, the annual shortfall already amounted to around 2,200 metric tons just for aluminium busbars in 2019.

S+S Industries plates its customers’ prefabricated busbars – made of copper, for instance – with zinc. “We realised the production capacities for these busbars were far too low throughout North America,” remembers Andrews. He had already noticed the sleek, high-quality Rittal enclosures on his customer visits, and when he heard about the new Rittal Application Center in Houston, he attended the opening event.

“When Moises showed me the Rittal Automation Systems solutions, I immediately knew these machines would be perfect for achieving a breakthrough on the North American busbar market,” reveals Andrews. “The systems at the RAC weren’t for sale, and it took us a while to win over the company management,” adds Abreu.

ROUND-THE-CLOCK OPERATION

Together with Andrews and company headquarters in Germany, he ultimately found an efficient solution. While waiting for the new machines to arrive from Germany, the RAC in Houston was to process a total of around 30 metric tons of copper for S+S. This period was also used to train S+S’s factory managers so they could plan the entire production operation and specify the changes at the RAC that were necessary to complete the order efficiently. Abreu monitored production, staff were taken on, and the RAC succeeded in processing all the copper within three weeks. Rittal also helped define an optimum material flow at S+S and prepare for the installation work. The customer ultimately took delivery of a turnkey solution.

Since then, the machines from Rittal Automation Systems have been operating 24/7 for S+S. “We’re aiming to process 2,200 metric tons of aluminium and 3,200 metric tons of copper each month,” explains Andrews.

SOFTWARE MAKES ALL THE DIFFERENCE

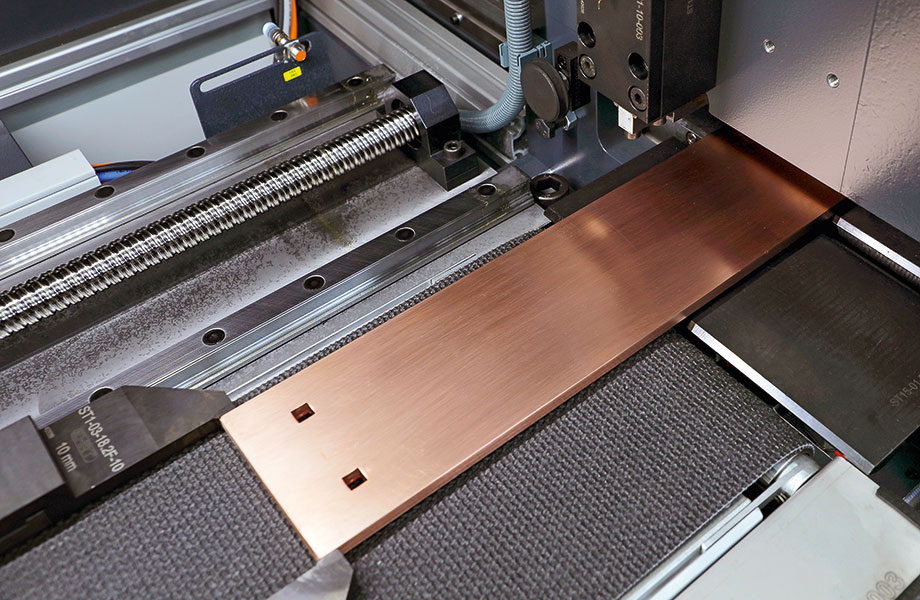

He is particularly impressed by the machine programming software. “You can obviously buy punching machines in the USA, too, but they don’t have the PowerCut software that makes it possible to work extremely efficiently. The required geometries can be imported very quickly, and the punchings can then be arranged on the strip. One special feature is the PunchPRO nesting software, which optimises material utilisation when arranging the punched parts on the copper busbar. We benefit from raw material savings of between four and five percent – a significant cost saving given the quantities we use,” explains Andrews.

The busbars always look the same. PowerCut makes it possible to define a whole host of variants in one program and select what is needed for a particular production operation from the range of geometries. As a result, numerous similar components can be programmed and managed efficiently. This, too, helps ensure the systems operate round the clock and don’t need to wait for punching programs.

SOPHISTICATED HANDLING

Thanks to their gantry system, the punching machines offer a sophisticated handling solution that enables them to be supplied with different materials and widths. They then automatically load the appropriate blanks themselves, meaning different orders can be completed seamlessly, one after the other. Andrews is also planning further automation steps to make production even more efficient.

FURTHER MACHINES ORDERED

“We have an excellent opportunity to make a lot of money here,” says Andrews. “Demand for busbars will grow further still in the USA in the coming years. We have the necessary electroplating capacities, we have direct contacts with the raw material suppliers and we can produce – the more the better. The market is still far from being saturated, so I’ve already ordered further machines and am having them air-freighted to Houston. Every day that we can’t meet demand, we’re losing money!” he explains.

Meanwhile, Abreu is continuing to build up the RAC. “We’re gradually getting the entire portfolio of machines from Rittal Automation Systems and can therefore provide our customers with comprehensive advice and support. However, demand for our machines is extremely high at present and we’re working with company headquarters in Germany on ways of offering faster deliveries. Enclosures and machines from Rittal are highly sought after in the USA!” he says.