Text David Schahinian ––– Photography

Just under 20 years ago, Willi Bruckbauer, founder and CEO of BORA, called time on conventional extractor hoods. His vision was to create a living space that meets people’s needs and makes them happy – every day. Besides meeting the highest technological standards, the revolutionary cooktop extractor system he developed also adds aesthetic appeal to any kitchen. A lot has happened since then. BORA has expanded its product portfolio and – thanks to its BORA X BO professional steam oven for homes, its refrigeration and freezing systems, and its range of dedicated accessories – has established itself worldwide as a multi-award-winning manufacturer of high-quality integrated kitchen appliances.

Over the years, the company’s workforce has increased to over 800. This growth inevitably took the original data centre to its capacity limits. The company could foresee that the existing IT infrastructure wouldn’t be able to cope with the growing demand and future expansion. When planning a new building at its Niederndorf site in Austria, more space was therefore also envisaged for IT.

One major challenge was making the right decision to ensure a future-proof power supply for the new data centre. Even the building’s architecture reflects two basic principles of the company. BORA has a policy of no longer using fossil fuels whenever they can be avoided. All its buildings have been switched to renewable energies, and even the electricity for the heat pumps comes from the company’s on-site photovoltaic system. “We try to get a lot of what we need from nature,” explains IT Systems Administrator Christian Dewina. At the same time, however, a high-performance, stable power supply is a must for the data centre. “Redundancy and high availability are vital for us, because BORA prioritises its customers’ interests and can’t afford any outages,” Dewina continues. The company was therefore looking for a partner that understood the importance of these requirements and could translate them into practical, high-performance solutions when building the new data centre.

USING WASTE HEAT AND HARNESSING NATURE FOR COOLING

BORA opted for Rittal. Cold water cooling technology was the obvious choice for cooling. After all, the River Inn flows right past the company premises and the site already had a well, which was integrated into the data centre’s cooling circuit. “Using well water for cooling reduces the amount of electricity we need to operate a chiller by up to 70 percent,” emphasises Sebastian Sautter, CEO and founder of Sautter ZT, which was responsible for planning the new building’s energy system. In the data centre, Liquid Cooling Packages (LCPs) from Rittal ensure the heat that builds up in the racks is reliably dissipated and the servers are supplied with sufficient cold air. Rittal also installed a chiller on the roof of the building for emergency cooling. This can supply the data centre with cooling power on an autonomous basis.

Combining the two cooling techniques was a challenge. As the most efficient option, well water should be used for cooling whenever possible, but it must also be ensured that the chiller springs into action as quickly as possible if the temperature does ever rise excessively. The “sweet spot” (i.e. the ideal combination) was ascertained on the basis of previous experience and practical tests.

The cooling circuit has a further purpose at BORA – almost 100 percent of the waste heat generated is used for the building’s heating system. “Even during cold winters, we can cover 20 to 40 percent of our heat requirements in this way,” reveals Dewina. The water is ultimately returned to the well, and the whole cycle starts again.

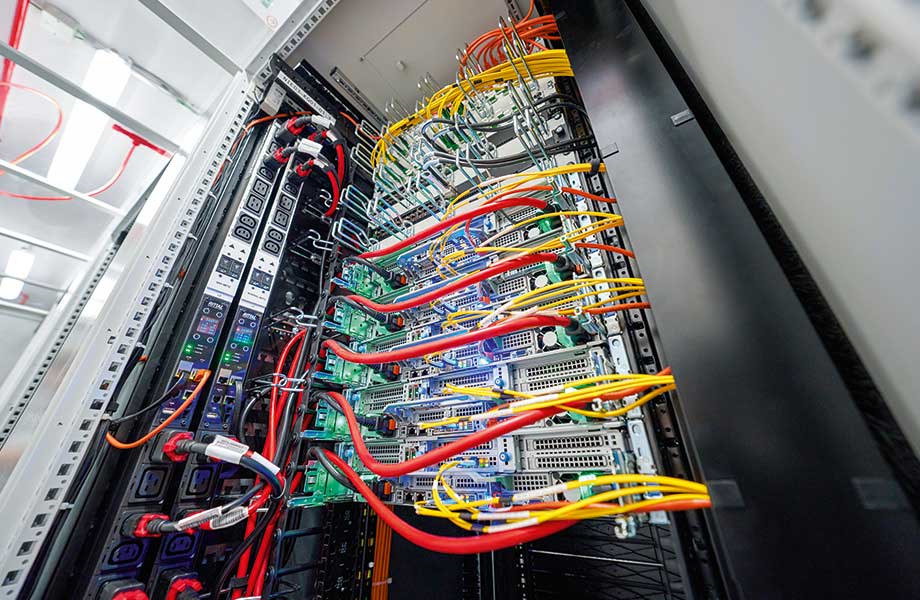

To ensure maximum availability, the server room and technology room were kept separate. “The technology room, which is the smaller of the two rooms, accommodates the uninterruptible power supply and the extinguisher system, amongst other things. The larger server room houses six racks, which is currently sufficient for the site, because we are pursuing a cloud-first strategy,” explains Dewina. Maintenance schedules, alarm installations and many other measures ensure the data centre fully meets the tier 2 standard. In collaboration with Rittal, outage scenarios were also simulated to test whether the fine-sounding plans actually stood up to harsh real-life conditions. “That was a very useful exercise. For one thing, it confirmed the concept worked and, for another, it showed us where certain details still needed to be optimised,” continues Dewina.

WON OVER FOR GOOD REASONS

A project of this kind doesn’t simply come about all on its own. Holger Jarrath from Jarrath.com, which specialises in information and communication technology, forged the initial link between BORA and Rittal. He has long enjoyed a good working relationship with both businesses. “IT is the beating heart of a company,” emphasises Jarrath. If it stops working, he says, the plant does, too, so good planning and foresight are essential. “We invited BORA to our production department in Herborn, where we presented our proposal and the necessary components,” explains Antonio Giffuni, a member of the Rittal field sales team. This even extended to power and cable management, which also plays a key role for the customer. “Although that involved a lot of detailed work, it was important, because it meant we could configure the IT racks in line with the customer’s specific requirements,” Giffuni adds.

The coherent overall concept, from climate control to power supply, and the excellent collaboration with Rittal ultimately won BORA over. After all, besides all the technical components, IT is also – and will always be – a matter of trust, given that sensitive data is involved. “BORA manufactures high-quality integrated kitchen appliances. The company knows what quality is all about and also recognised the quality we offer,” sums up Giffuni.