Text Meinolf Droege ––– Photography

Kaco is based in Neckarsulm, in south-western Germany. Part of the Siemens Group, the company is supplying the right products at the right time with its inverters. All photovoltaic systems require these devices in order to transform the direct current the systems generate into the alternating current that is needed for our energy grids. Kaco has been producing efficient, low-loss solutions of this kind for a number of years – primarily for larger, high-performance systems.

Kako’s technological enhancements are just as dynamic as the development of renewables. These enhancements also optimise user-friendly operation, production costs and the carbon footprint. Potential improvements were investigated as part of a new development called blueplanet 125 NX3. Amongst other things, the pedestals – which are also used to secure the inverter in place at the location of installation – were potentially to be made from injection-moulded plastic instead of die-cast metal. As Kaco Managing Director Matthias Haag explains: “The inverter was developed on a totally new platform. During this process, the market trend towards much bigger PV installations intensified, so we’ve designed the new device for an output of 120 kilowatts. However, doubling the power required us to completely redesign the housing. The die-cast aluminium pedestals were another topic of discussion.”

REDUCED CARBON FOOTPRINT

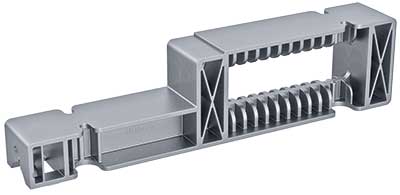

LKH has optimised the pedestal, which is subject to high mechanical requirements, for various load scenarios. Significantly reducing the wall thicknesses made it possible to reduce the weight, while still ensuring the component is highly robust for industrial use. LKH had also recommended a stiffer – recycled – material with an increased glass fibre content of 30 percent, and had used this in series application. This significantly reduces both costs and the carbon footprint on a sustainable basis. A further benefit of the new design is that the pedestals emerge from the injection-moulding machine as ready-to-install components with a wide range of integrated functions and no longer need to be assembled from several different parts, which leads to further cost savings.

Kaco had previously almost exclusively used metal for its designs. As Heiko Daub, Head of Mechanical Engineering at Kaco, explains: “Due to the size of the device and the expected quantities, we started predominantly developing components made of plastic for the inverter – even before LKH came into the picture. To start with, we designed the pedestal itself in plastic, for instance, and LKH very quickly confirmed the project’s feasibility.” He also reveals that, thanks to appropriate simulations for a variety of load scenarios, LKH eliminated any concerns regarding high mechanical stresses and fatigue strength. Haag comments on the thinking behind the various load scenarios: “We wanted to integrate several functions – namely, by also using the pedestal as a handle and a wall bracket. That makes handling much easier during assembly.” Daub describes how the project continued: “Even before it got the order, LKH was very proactive and started optimising our design and carrying out calculations. It also considered UL approvals for the plastic, long-term stability and the use of recycled material.”

FURTHER COMPONENTS OPTIMISED

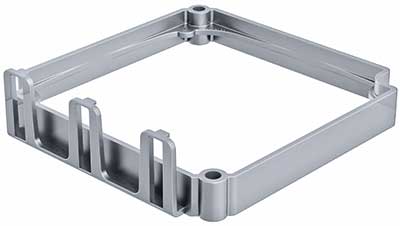

With this first order, LKH proved its credentials to Kaco – not just as a supplier, but also as a development partner. One way in which it achieved this was to highlight further optimisation potential for the new inverter, for example relating to the fan frame and its cover. Design measures and filling simulations made it possible to drastically reduce the warpage of both components and thus improve the assembly process at Kaco.

Further tweaks are still to be made. For example, it is conceivable for LKH to supply the cover already equipped with a foamed gasket in order to simplify subsequent steps at Kaco and potentially achieve considerable savings as a result.

Something all the new components have in common is their added value. Besides their robustness and suitability for industrial use, this includes cost-effective production, an assembly-friendly design with a high level of functional integration, and favourable eco credentials. What’s more, all components are made from the recycled material.

Daub sums up the collaboration as follows: “The excellent and, in some cases, pre-emptive preliminary work involving calculations and the like was just as vital as the equally impressive expertise relating to materials, design and plastics production.”