Text Hans-Robert Koch ––– Photography

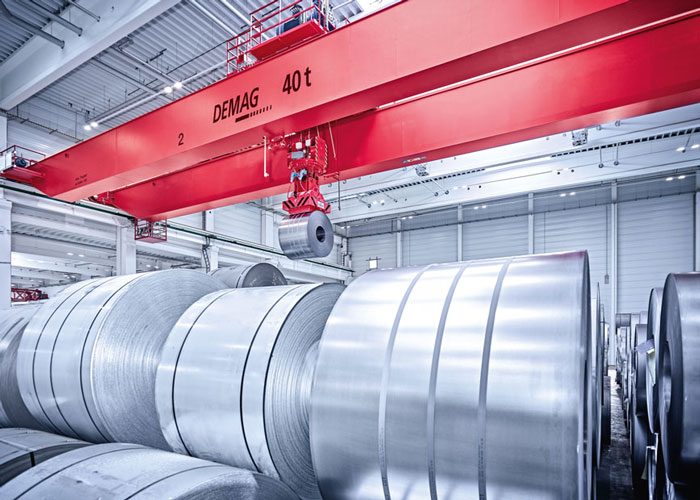

There is a great deal of interest in green steel – from both end users and steel processing companies. For instance, demand for cars and household appliances that have been manufactured in an environmentally friendly way is rising. As companies work hard to decarbonise their supply chains, the issue of finding reliable green steel suppliers is becoming ever more pressing. Initial volumes of this green steel are now coming onto the market. Stahlo has been supplying its customers with steels produced via the “Peine electric arc furnace (EAF) route” since 2021. These steels have the Stahlo secures supplies of green steel Stahlo D+ classification – in other words, they have a substantially reduced carbon footprint due to the electric process that is used to produce them. This process cuts emissions by over 60 per cent compared to the conventional blast furnace (BF) route. Stahlo has now signed a partnership agreement with Salzgitter Flachstahl to secure supplies of SALCOS® (Salzgitter Low-Carbon Steelmaking) material, provisionally from late 2025. Consequently, one of Europe’s most modern steel service centres is ensuring the availability of steels in emissions class C+ or B+ based on Stahlo classifications (www.stahlo.de/en/classification-label).

RELIABLE SUPPLIER

“A great many of our customers are following a decarbonisation roadmap, which sets out reductions in emissions over the coming years in logical steps. Many customers have already planned and made valuable progress within their direct sphere of influence (Scope 1 + 2). However, upstream emissions are another key lever when seeking to optimise your carbon footprint, and it is the upstream suppliers, such as steel suppliers, who are responsible for these. Our aim is to help our customers achieve their carbon-cutting measures in steel procurement for the coming years and meet upstream Scope 3 requirements,” says Oliver Sonst, Managing Director of Stahlo. “We are therefore delighted to be expanding our long-standing, trusting partnership with Salzgitter Flachstahl even further, thus making us a reliable supplier of green steel for our customers moving forward.”

Ulrich Grethe, CEO of Salzgitter Flachstahl GmbH adds: “The Salzgitter Group works in close collaboration with customers and partners to achieve climate targets – fully in line with our strategic Mission Partnering for Transformation. The collaboration with Stahlo again demonstrates that customers are following our lead on the path to green steel production. Our many partnership agreements show that markets for green steel are becoming more established in various customer sectors.”

THE CLOSED LOOP TARGET

With its own ideal carbon footprint of less than 3.6 kg carbon dioxide per metric tonne of processed steel, the steel service centre is supporting its customers in optimising the product carbon footprint (PCF) of the steel products they purchase. Stahlo supplies a sophisticated range of flat steels to companies in the Friedhelm Loh Group, such as Rittal, and customers in the manufacturing and automotive industries.

Moreover, Stahlo and Salzgitter Flachstahl are planning to complete the recycling chain. Stahlo could return sorted, pure scrap directly to Salzgitter Flachstahl, thereby making closed loop recycling a reality. What’s more, Stahlo, as an industry pioneer, is continuing to press ahead with supply chain transparency and secure certificate management to strengthen trust in the new “green” supply chain ecosystem. “Being an independent steel service centre puts us in an ideal position to satisfy the need for reliable information,” says Sonst. With the “Steel Gate” application presented at Euroblech 2022, the steel specialist offers a solution for implementing carbon tracking along the steel supply chain digitally, transparently and, above all, securely. This solution makes use of blockchain technology.