Text Annedore Bose-Munde ––– Photography

Mr. Kunzel, why are energy storage systems growing in popularity to such an extent right now?

Essentially, energy storage systems support efficient energy management. This means self-consumption can be optimised, for example by storing power generated by photovoltaic installations during the day and then using this at night or when it’s overcast. Peak shaving is a further typical application. Storage systems can step in and shave load peaks at the precise point in time when cooling systems are starting up or a large number of vehicles are being charged simultaneously.

Certain countries also use time-dependent electricity tariffs, and we have introduced a time-of-use function for this scenario. The storage system charges up at times when power is inexpensive, and this power is then used during expensive periods. Storage systems make it possible to achieve zero feed-in at the grid connection point, which might avoid an expensive expansion of the grid connection.

Energy storage systems are technically challenging. What role does the enclosure play?

An important one, is the short answer. One of the first steps for us is to find an enclosure that is suitable for the battery technology. The enclosure system also needs to meet basic contact hazard protection requirements. An appropriate IP protection category is important, as is the earthing concept, of course. The enclosure system also forms part of the TESVOLT safety concept. Our systems are always certified by the TÜV inspection agency – and that includes the enclosure. Battery modules are heavy, so the enclosure also needs to be very robust.

What loads must an enclosure actually be able to withstand?

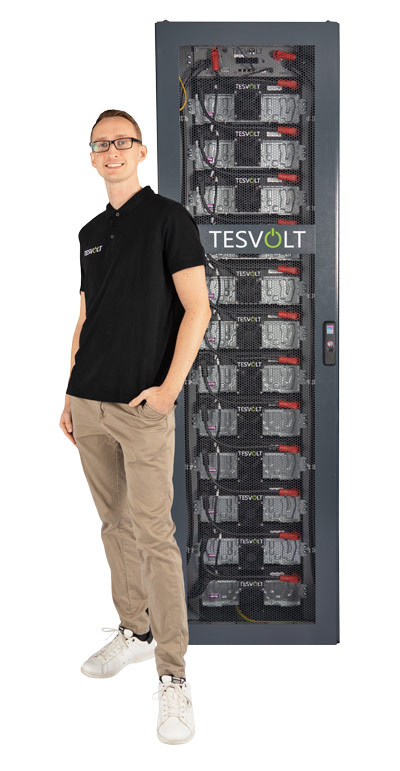

The largest system we currently use consists of 12battery modules – each weighing 56kilograms – and the necessary peripherals. All that adds up to around 600 to 700 kilograms. There’s also the enclosure itself, which weighs about 150 kilograms. The enclosure system must have a sufficiently stable design to prevent any deformation. Given that our solutions are scalable, it must also be possible to extend the enclosures by baying them, for instance. Another important factor is ensuring straightforward handing – our modules must be easy to install.

At what stage of the development process does the enclosure enter the equation?

When we are preparing a new product concept, we consider the enclosure very early on. A specification that defines all the requirements is then drawn up. This forms the basis for the joint development and engineering process for the appropriate enclosure system. Following a number of iteration loops based on CAD data, an initial prototype is produced. The subsequent test installation of the modules and components indicates any final adjustments that may be required. The second prototype that follows this process is then normally the series prototype.

What do development partnerships mean to TESVOLT?

It’s vital to tackle the joint design engineering tasks together as early on as possible. All changes made later on can become expensive. We very much appreciate it when – as with Rittal – our development partners are proactive, coming up with suggestions and ideas. We were also happy to draw on the complementary skills of Rittal, such as its thermal expertise. The TS8 systems were the first joint project with Rittal. That was in 2016, not long after our company was founded in 2014. We regard Rittal as both a development partner and a supplier. We value its delivery reliability and also the quality Rittal ensures with its robust and durable products.

Can you give another example of a joint project?

One new development at TESVOLT is our E-Series with enclosure technology and a ventilation concept from Rittal. The new model has a higher energy density and, accordingly, a higher thermal load – all part of the challenge when designing the enclosure. Rittal carried out simulations in advance that focused on the enclosure’s temperature behaviour. The air inflow and outflow were investigated, and minimum spacing was defined to ensure external air for cooling can be drawn in. With the new E-Series, the enclosure design is now much more open. Greater attention has been paid to climate control, so we can ensure the battery is at the ideal temperature.

Thank you very much for talking to us.