Text Hans Robert Koch ––– Photography

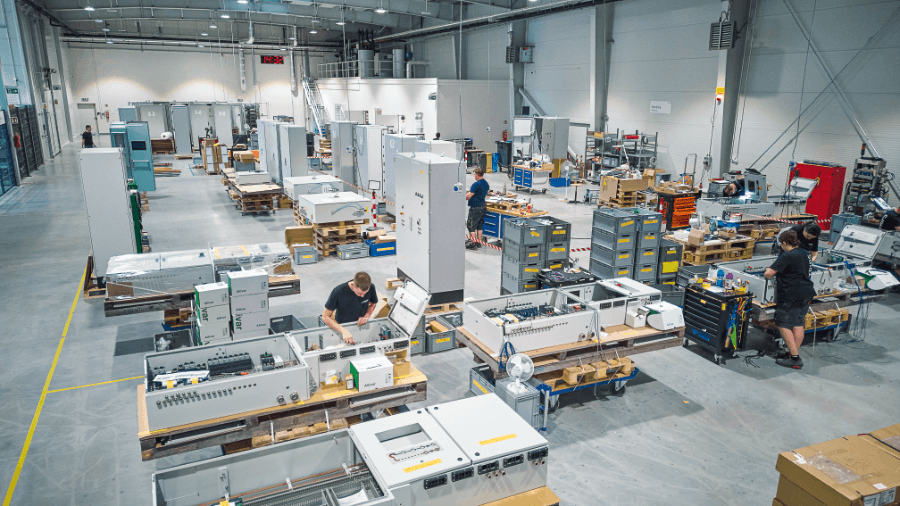

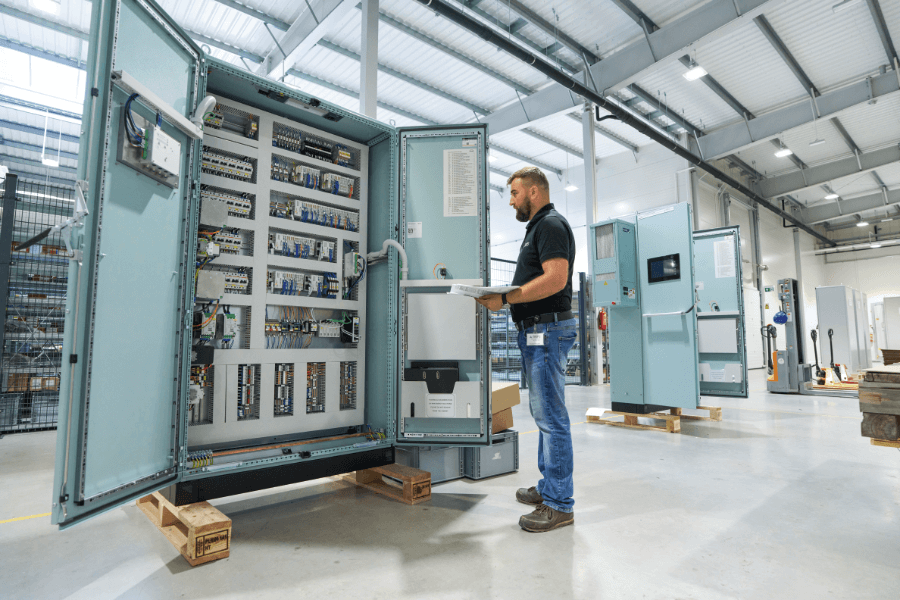

TRIPS doesn’t think small. That immediately became clear when we arrived at the company’s premises in Krapkowice. The people here are clearly proud of the large, ultramodern plant that started operating just last year and has a production area of approximately 4,000 m2 , where over 80 employees carry out large projects and manufacture systems for the energy market, mechanical engineering and other sectors.

Greenfield site

The plant is a greenfield development in the truest sense of the word. It is also an investment in the future, with plenty of scope to grow. An expansion on the 18,600 m 2 company premises has always been part of the plan. “We are ready for the future, have planned for rapid growth and can implement two further expansions of our production area at the site,” says a proud Lukasz Kowalski, Managing Director of TRIPS Automatyka Polska.

A glance at the development plan reveals just how far into the future the company is looking. The routes for additional supply lines to expand the production area have already been prepared, along with the boreholes to make further use of geothermal energy. On the subject of sustainability, the use of renewable energies was a key consideration at the planning stage. Geothermal systems heat and cool the new plant. Together with a ventilation system that benefits from heat recovery and a 180 kW photovoltaic installation on the company roof, these systems ensure maximum energy efficiency and optimum net zero credentials.

More space for big things

Having so many prospects for the future is something new. It used to be a different story. Expanding the old production site in Wykroty, where TRIPS has been manufacturing on a smaller scale since 2016, was impossible and bottlenecks first started forming some years ago. “We have very customer-specific projects and need space to accommodate systems for large projects,” explains Kowalski. “To expand our production capacities, we planned the new plant building to make the production area very modular and flexible so it can easily be adapted to the relevant customer project,” he adds. Even large systems, shipping containers and eHouses don’t pose any problems. Getting them into the building and fitting them out is straightforward, and they can remain in the production department for weeks and months.

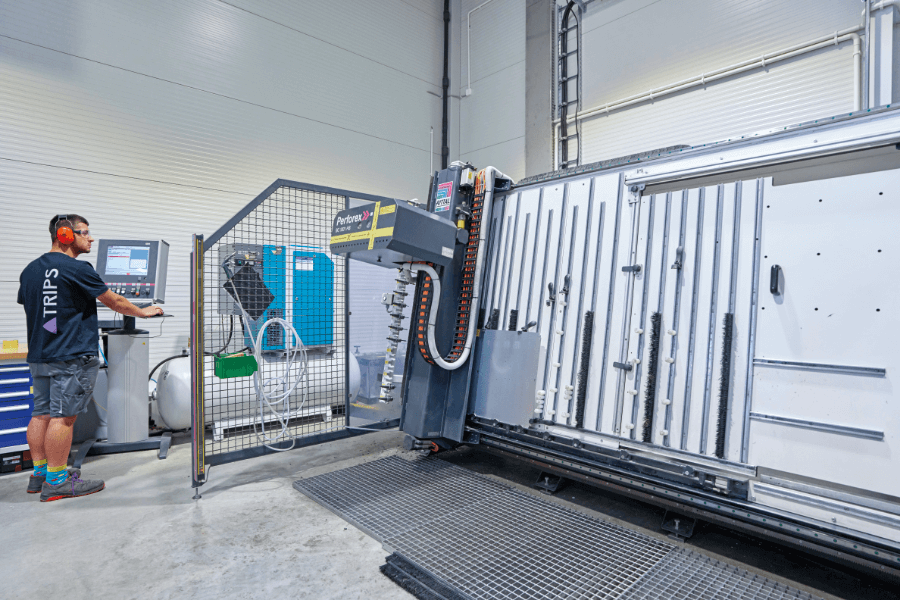

Maximum automation

To improve production efficiency and quality, TRIPS uses integrated automation solutions for its enclosure machining, cable processing and system testing. There’s no disruptive noise from drilling and milling work either. Staff can concentrate and work on the enclosures in peace. The noisy machining work has been “banished” to a separate production area, where a Perforex machining centre from Rittal processes enclosures and panels on an automated basis. “Thanks to the Perforex, we can automate up to 95 percent of all drilling and milling work,” says Kowalski.

Fully digital

When it comes to digitalisation, the company is not doing things by halves and is adopting a holistic approach. The digital workflows extend from the engineering section all the way through to the cutting-edge workstation at the enclosure, where specialists call up precise details of circuit diagrams and wiring routes on monitors. Printed circuit diagrams are no longer needed. “The Eplan software and its integration into the machine technology helps us create a fully digitalised workflow – from planning all the way through to the finished product,” explains Kowalski. The hardware engineering was implemented on the basis of Eplan software in 2024, meaning commissioning and services are now also possible. “We are intending to roll out this comprehensive solution programme further over the next year,” reveals Kowalski.

Seeing skilled staff as an asset

However, it has so far only been possible to automate certain aspects of production. “Some 90 percent of our production operations are customer specific and therefore still involve a great deal of manual work,” admits Kowalski. Well-trained staff are needed. “Skilled workers are vital for success but are in short supply in Poland, too. We invest heavily in the training and development of unskilled workers,” he emphasises. While the new plant was being built, TRIPS was already looking for staff and providing them with specific training for the new processes, making use of a temporary plant nearby. The company has also started collaborating with the technical college in Krapkowice. This means young people can complement their theoretical knowledge with practical experience at TRIPS – very similar to the standard three-year training programme in Germany.

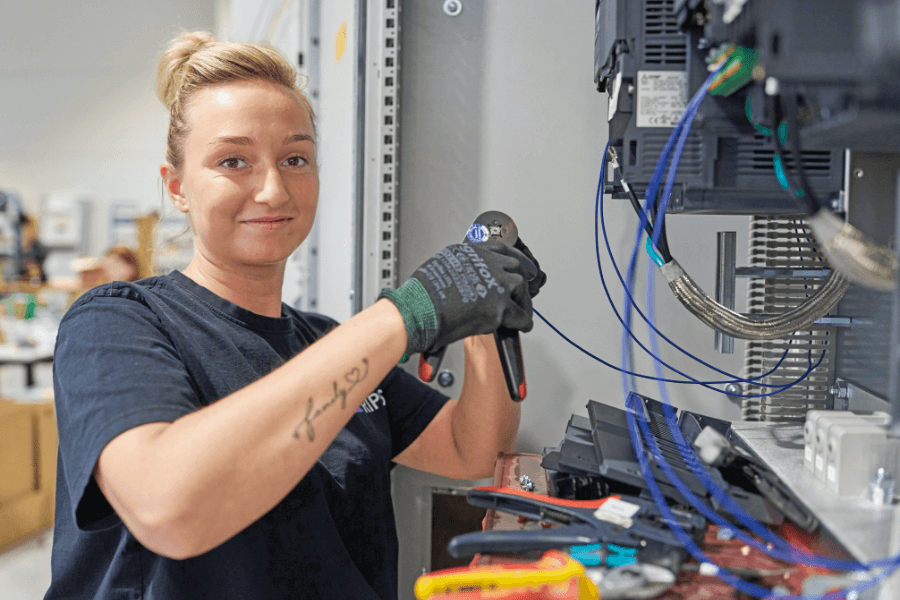

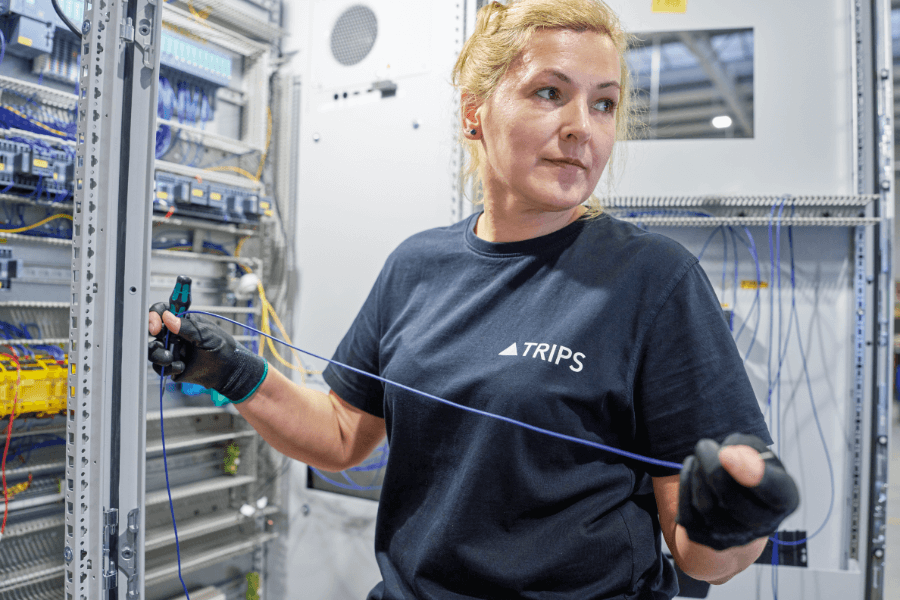

Women with precision

While walking through the plant, the high proportion of women working in production, especially in the enclosure wiring section, is striking. There is a good reason for this, as Kowalski explains: “A large number of our female staff have many years of prefabrication experience, and women generally have a better feel for precision anyway, which is vital for our projects.”