Text Ulrich Sendler, Hans-Robert Koch ––– Photography

While high performance computing (HPC) may once have been a niche area that was the sole preserve of hyperscalers such as Microsoft, Google or Amazon, that has not been the case for quite some time now. In light of Industry 4.0 and the Internet of Things, companies are facing ever-growing requirements. Nowadays, 3D simulations of future products and processes are part of day-to-day business even in smaller companies. Computer- aided engineering (CAE) – the simulation and calculation of computer models – is ranked third among the applications that generated the biggest income on the HPC market in 2020. Chalking up annual revenue of 1.538 billion U.S. dollars, CAE came in below governmental labs and research institutes, and above biosciences.

RAPID GROWTH – HPC AND THE CLOUD

HPC cloud-based applications are developing particularly rapidly at present. According to calculations by analysts at Hyperion Research – the former IDC HPC specialists – cloud HPC is set to grow by 16.7 per cent between 2020 and 2025, while the HPC market as a whole is “only” growing by 7.9 per cent. Even in 2021, the cloud market share represented approximately 16 per cent of the HPC server market. Hyperion anticipates that this figure will rise to 19 per cent by 2024. The analysts are working on the assumption that almost one in every two HPC users will transfer their on-premises workloads to the public cloud over the course of the next twelve months.

The automotive industry provides a good example to help make sense of this development. The expectation is that we will see a rapid switch to electric mobility in this sector. What’s more, in addition to “normal” product development, manufacturers are working on sophisticated technologies such as driver assistance systems, with autonomous vehicles as the final step. Mercedes-Benz Group AG is not the only automotive company that has long been using high performance computing as a standard tool for such tasks. The digital twins of the vehicles alone comprise tens of thousands of part models, and when it comes to simulating their behaviour, electronics and software need to be incorporated, too. It is only in advertising videos that all this appears to work on a tablet – in real life, everything happens in data centres.

LESS CO2 – AN ECONOMIC REQUIREMENT

However, assuming that power supply and cooling are handled in the same way they always have been, this dramatic development of data-intensive and storage-intensive applications is completely at odds with the second challenge that industry needs to tackle quickly and rigorously – climate neutrality. A new approach is therefore needed for HPC applications. After all, reducing their CO2 footprint and becoming both sustainable and climate-friendly is increasingly becoming a very real economic necessity for industrial companies.

When it comes to moving high performance computing in a more environmentally friendly direction, Mercedes-Benz Group AG is leading the way. In December, the premium manufacturer collaborated with Infosys, an international provider of digital services and consulting, to relocate its HPC workloads for virtual crash tests and for the development of autonomous driving technologies to the Lefdal Mine Datacenter in Norway.

MERCEDES-BENZ GROUP AG – CLIMATE-NEUTRAL BY 2039

The Mercedes-Benz Group AG has set itself a tough target – “Ambition 2039”: “We want to be CO2-neutral by 2039. We take a holistic approach to climate protection. When setting our objectives, we take all the links in the automotive value chain into account, from development, the extraction of raw materials and production through to the usage phase and recycling.”

Why did the Mercedes-Benz Group AG decide on the data centre in Lefdal rather than one of the many competitor solutions that are now available? Jan Brecht, CIO at Mercedes-Benz Group AG, explains the decision as follows: “Not only do we benefit from natural cooling in a cold climate, but all the power we use is green electricity. This initiative is another important milestone on our journey to climate neutrality.”

IT DOESN’T GET ANY GREENER THAN THE LEFDAL MINE DATACENTER

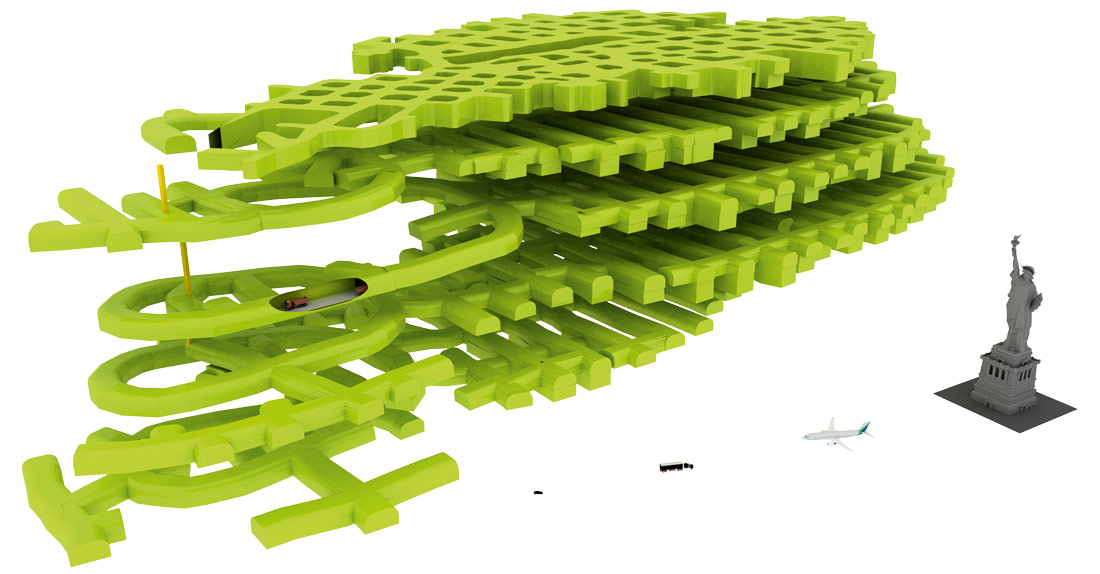

The Lefdal Mine Datacenter – a specialist in high performance computing (HPC) – is quite simply one of the greenest in the world and a role model in many respects. In December 2021, it won the ITA award in the “Innovative & Contributing Underground Spaces” category, which attracted nominations from 78 nations. It works with 100 per cent renewable power and the longterm costs are considerably lower than in Germany, for example (4 cents/kWh instead of 18 cents/kWh in 2021). Compared to other data centres, the total cost of operation (TCO) is around 60 per cent lower. Its power usage effectiveness (PUE) is between 1.1 and 1.10, compared to an average of 1.7 in Germany. There are no CO2 emissions.

Located below sea level, the data centre uses the cold water from the fjord at a steady temperature of 8 degrees Celsius for cooling purposes, and the water usage effectiveness (WUE) is also zero. In addition to these extremely green credentials, LMD also has 120,000 m2 of white space and a capacity of 200 MW. What’s more, the data centre is located in a country where European data privacy is enshrined in law.

OT INFRASTRUCTURE – FLEXIBLE AND SCALABLE

The technical solution behind the OT infrastructure was also a key factor for Mercedes-Benz Group AG. Ever since LMD was founded, the Friedhelm Loh Group and its companies German Edge Cloud and Rittal have been on board as strong co-owners – but that’s not all. Rittal also supplies the technological framework for successful offerings. The basis is RiMatrix Next Generation (NG), a modular system platform for developing all kinds of OT infrastructure. With this solution, Rittal has taken the standardisation of data centre infrastructure to a whole new level, enabling versatile scalability and flexibility. Solutions for white space and containers are injecting speed and dependable standards into the OT infrastructure expansion at LMD.

In terms of the project with Mercedes-Benz Group AG, Rittal is supplying system solutions for racks, cooling, power supply and security. As Martin Kipping, Vice President Global Datacenter at Rittal explains: “We welcomed a Mercedes- Benz Group AG delegation to our container manufacturing facility in Ewersbach and ran joint workshops in Herborn and Sindelfingen. Mercedes-Benz Group AG was impressed by the standardised modularity of our infrastructure solution. What's more, even though the LMD is fundamentally an open platform, we are its preferred technology partner.

Although Mercedes-Benz Group AG is starting out at LMD with crash simulations and technology development for autonomous driving, there are certainly no technological barriers to including other HPC workloads, too. The modular infrastructure also enables speedy implementation. Instead of taking years to develop and configure the data centre, Rittal standards mean this can be accomplished in just six to eight weeks. The first sections of the HPC data centre that Mercedes-Benz Group AG is relocating to LMD are to go live in early 2022.

Jørn Skaane, CEO of LMD comments: “The combination of our data centre and Rittal technology is the perfect match for customer requirements. That doesn’t just apply to our customers in industry either.” He is referring to the acquisition of another major customer in late 2021, namely Sigma2, owner of Norway’s national supercomputers and storage facilities. Through the Norwegian research infrastructure services (NRIS), Sigma2 also has close links to the Universities of Oslo, Tromsø and Bergen as well as to NTNU, the Norwegian University of Science and Technology.

The data centre located in the former mine is winning major and experienced customers right now specifically because of the flexibility and scalability that LMD is able to offer in partnership with Rittal – for everything from a ready-to-use data centre container through to white space that can be developed in any way at all. “These aspects mean that, in the future, we will also attract many smaller companies and organisations that are increasingly recognising how cloud and co-location in green Norway can really benefit their own data centres,” Skaane says.