Text Gerald Scheffels, Birgit Hagelschuer ––– Photography

Czech Republic or Poland? In Germany’s neighbouring states, there are many panel building and switchgear manufacturing companies performing at a high level. In some respects, manufacturing at these companies takes place under much more favourable conditions – lower wages, substantially lower energy costs and less red tape…

So when a building automation business is looking for a company to plan and produce its enclosures, why would it opt for Hade Automation, which is based in the southern German town of Orsingen? It’s a fair question, especially since Hade Automation’s customers are often large companies that don’t shy away from cross-border supply chains.

Markus Klopfer, one of the two Managing Directors, provides the answer. “It’s true that, with 24 employees, we’re a relatively small enclosure manufacturer, and we also operate in a high-wage country – but our staff are skilled and we work with a high level of automation,” he explains. Maik Reichle, the other Managing Director, adds: “Providing processes work consistently and we have the data we need, we can build switchgear in Germany in an automated and competitive way. We are working for several global players who have clear ideas about their enclosures.”

MANUFACTURING WITH PLANNING DATA

How does this work in practice? At Hade Automation, project work starts directly on a planning platform – with Eplan, to be precise. Klopfer explains: “Ideally, we use the 3D data from Eplan to draw up a quote. We enter the parts list into our system and can then perform very precise calculations.”

From the company’s perspective, this thorough planning right from the outset also delivers significant competitive advantages, because production is incorporated, too. For instance, the company invested in an automated CNC machining centre. “We were quick off the mark in this respect, but also had a real pain point at the time – lots of versions of ready-made enclosures in stock, but seemingly never the right one for any given customer. Machining on site really boosted our productivity.”

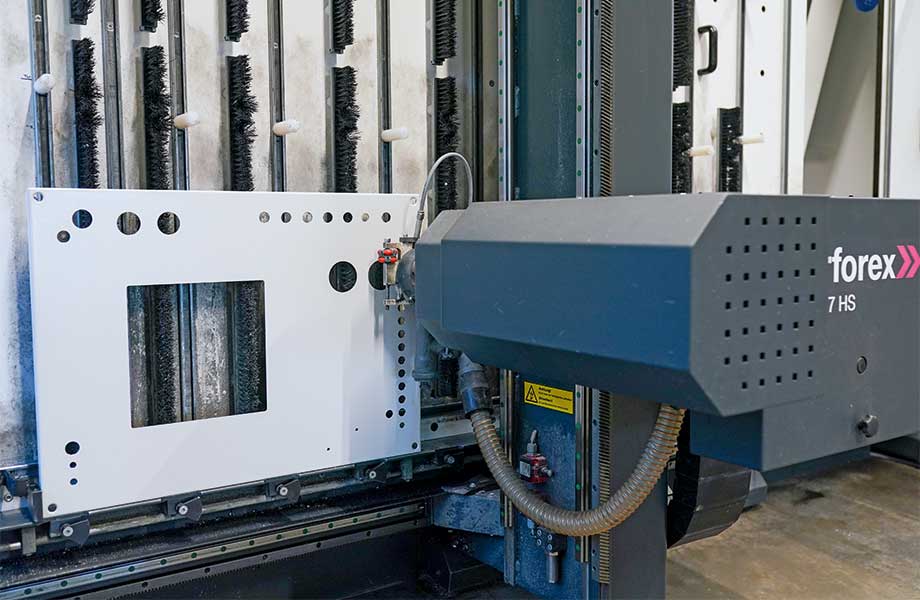

The second generation of machinery is now in use – a Perforex system from Rittal Automation Systems for machining enclosures and panels. “With the Perforex system, our end-to-end planning and production are even more efficient – and we benefit from the interplay with Eplan, too. We’ve drastically reduced our stock levels, and yet can now supply our customers so much faster than before. The enclosures are machined automatically and each customer can choose where the cooling unit is to be positioned, for example,” Klopfer explains.

While Hade Automation handles its end-to-end enclosure planning and production in house, the wires are processed by an external service provider – also on the basis of Eplan data.

ENERGY AS A NEW LINE OF BUSINESS

The company’s recipe for success also includes being open to new lines of work and business. Around two years ago, for example, Hade Automation tapped into a new sector. “We have always planned and built control equipment for the energy generation sector – such as for photovoltaic systems – and for increasingly powerful currents. Major energy suppliers in our region who are looking for partners in switchgear manufacturing have come to us. They like working with small companies that respond quickly to customer requests – and they make it a deliberate policy to do so. We can really shine in that regard,” says Klopfer.

From Hade Automation’s perspective, the obvious thing to do was also to incorporate the additional processes into Eplan and create a direct link between planning and production. The “Copper” module is available in the Eplan portfolio for this purpose. This makes it possible to plan and visualise copper busbars in 3D – and process the data in the Perforex, for which the company has purchased a busbar module. “We simply insert the module into the machines and can then fully process our Rittal busbars, so that NH slimline fuse-switch disconnectors can be fixed in place, for example. This can call for a good 50 drilled holes per copper bar. We send the precise data directly to the machining centre,” says Klopfer.

SCALED AUTOMATION

With this high level of automation, Hade Automation is disproving the commonly held belief that processes of this kind are more suitable for big enclosure manufacturers. “Automation and end-to-end use of data on one central platform are delivering clear optimisation effects for our company, even for a batch size of one. This is already being reflected in the speed of our production. We can now wire two enclosures in the same time that it used to take us to wire one,” the managing director explains.

Current prospects also include cross-disciplinary 3D planning of the building technology as a BIM model. “That’s coming – and we’re ready for it. We’re planning everything digitally in BIM for a pharmaceutical production plant in the Munich area. The 3D model of the enclosures is being integrated into the model in such a way that you can virtually open the door and look inside it,” explains Klopfer.

All in all, the company feels fully prepared for the future – and, according to Klopfer, one aspect of that future has already been identified. “It’s all about the energy transition – we’re getting lots of enquiries about modernising energy technology switchgear,” he says.