The mere thought of such a power failure is enough to make logistics managers break out in a cold sweat. It would no longer be possible to place goods in storage, and customers would be left waiting in vain for their packages. The standard next-day delivery promise of online traders would be at serious risk. In many cases, the cause of such an outage is trivial. A tool that’s been left behind or a screw is all it takes to trigger an arc flash in switchgear, with dire consequences. Depending on the type of arc fault protection installed, parts of the system may be destroyed or at the very least badly damaged. In the worst-case scenario, it can take several weeks to repair – a period during which the logistics centre is restricted to emergency operations.

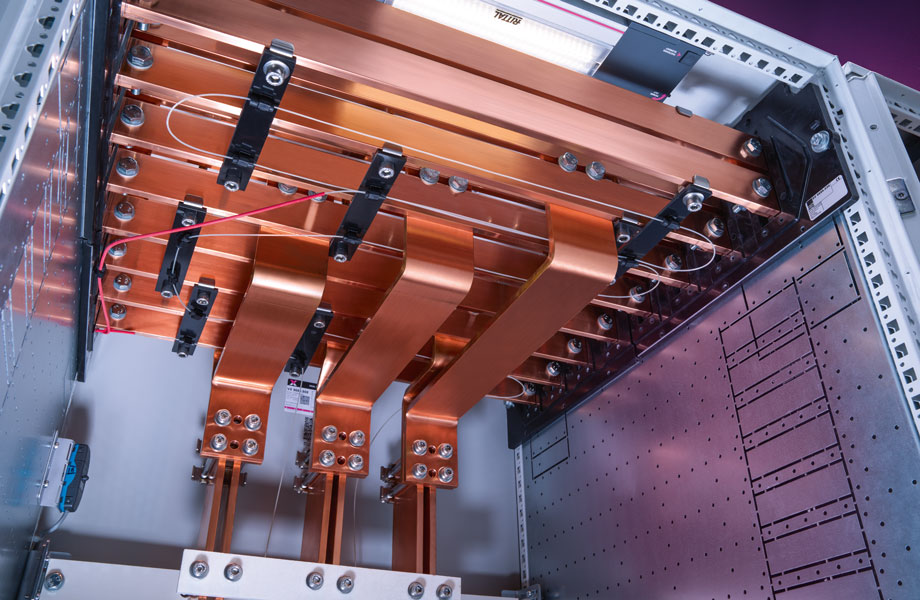

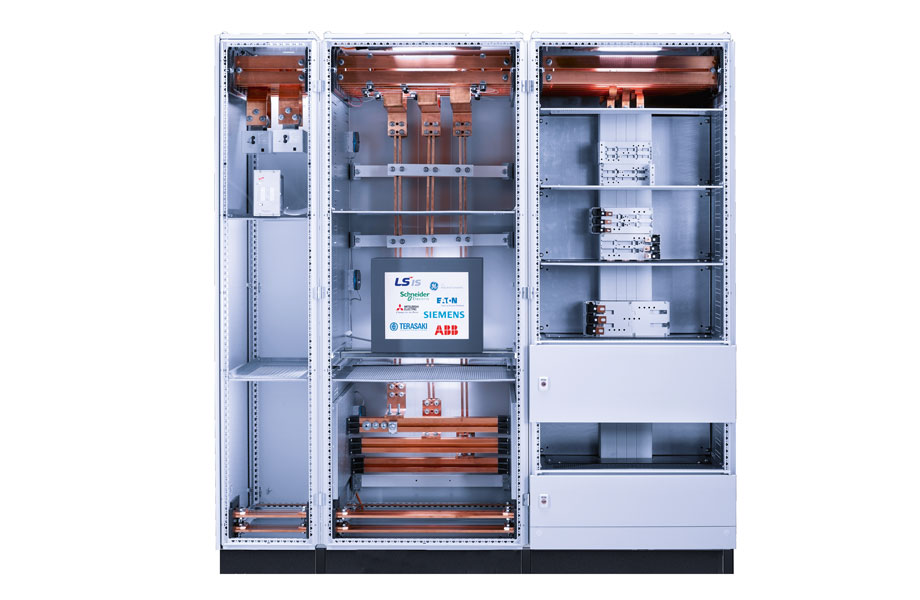

But what can be done to prevent problems of this kind or at least limit their duration? “That’s the question plaguing many managers,” says Jan Kretzschmar who, in his role as head of the Low/Medium-Voltage business unit at Elektro Vieweg, planned the power supply systems for two logistics centres operated by one of Germany’s largest online mail order businesses. The energy consumption of these centres is extremely high. Four low voltage main distribution boards (LVDBs), each of which is supplied via two separate medium-voltage transformers, provide the electrical energy for the two centres. Together, these installations have a total rated current of 17,000 A. One of the key requirements when planning the LVDBs was Class C active arc fault protection. According to Kretzschmar, Elektro Vieweg is increasingly encountering these kinds of requirements: “The demand for arc fault protection has been growing strongly for a number of years.”