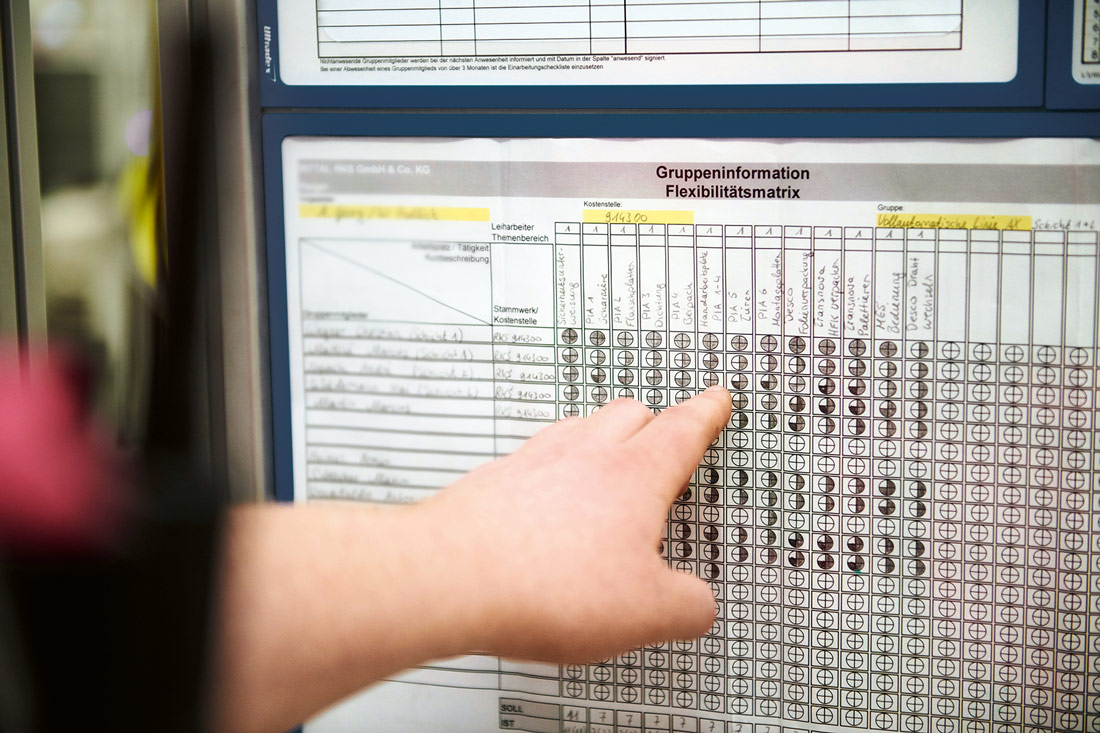

Digital transformation is something Alexander Koroljow has coped with for quite some time now. On shift at the Rittal plant in Haiger, he uses a touchscreen to monitor the system that manufactures doors for enclosures. It’s just an ordinary working day for the 45-year-old. The production facility was opened in 2018 and is fully aligned with highly efficient Industry 4.0 structures. The fact that Koroljow is so comfortable with all these new technologies is certainly down to his sense of curiosity, but also to the training his employer offers. In 1997, he started at Rittal as an unskilled worker but, over time – around 50 Saturdays in fact – he completed an in-house course to become a machine and system operator. Today, he is part of a digital manufacturing process in a smart factory. It is an achievement he attributes at least in part to the fact his employer will take staff who are willing to learn and open to change and integrate them into the digitalization process of industry 4.0. After all, the aim at Rittal, a subsidiary of the Friedhelm Loh Group, is for machines to work hand in hand with people – not replace them. “Given all their experience and know-how, staff play a decisive role – one that is only going to become more important. Equally, requirements profiles will also change,” explains Gero Düweke, Project Leader Qualification in Haiger.

The magazine of Friedhelm Loh Group

The magazine of Friedhelm Loh Group