The magazine of Friedhelm Loh Group

The magazine of Friedhelm Loh Group

Text Sabine Spinnarke, Dr. Carola Hilbrand ––– Photography

Rittal elevates enclosure engineering to a new dimension: from one-off, handcrafted sheet metal units to professional serial production

Following the idea to standardise enclosures, and to serially produce and deliver them ex-stock, Rittal founder Rudolf Loh hit the mark with the AE (the “AllerErste” – meaning the “very first”) in 1961. However, the market was initially sceptical. Enclosures off the rack? For years, the small team led by Rudolf Loh and Norbert Müller worked to change people’s minds. They were proven right. In 1971, Volkswagen elevated the Rittal enclosure to the worldwide factory standard. Today, Rittal supplies customers around the world – even delivering serially produced enclosures within 24 hours in Germany. Simplifying the complex through standardisation – that is the guiding principle. It was the early inspiration for the company, and remains the driver of all its innovations today. It is standardisation that makes the fully digitally integrated production of the AX possible at Rittal’s Haiger plant.

A new dawn: Rittal reinvents the enclosure and lays the foundation for “Rittal – The System”.

The AE was produced in four sizes. However, as industrial automation started to pick up speed, the Rittal team quickly realised that flexibility was the key. Enclosures were no longer regarded as rigid units, but as flexible modular systems. With the development of the RS modular enclosure, Rittal took the first step towards a system that could be expanded – in terms of height, width, depth and accessories. At the same time, the components in the enclosure increased in power density. This called for new cooling concepts. Rittal entered the race in the “air conditioning” division, and later, the “power distribution” division as well. This systematic approach remains definitive to this day. The goal is to create endless possibilities for expansion – through modularity, flexibility and speed.

Electrical planning and enclosures from a single source – Rittal does software too

A man, a woman, and a dog in an old supermarket – that is how Dr Friedhelm Loh described his first impression of the developer couple, Harald and Renate Wiechers. They had written a small, basic program that could be used to create circuit diagrams on the first affordable PCs with a graphic user interface. Rittal immediately recognised the opportunities this provided. Now it was not only possible to offer enclosures, but to enter the value creation chain one step earlier: during engineering. Wiechers & Partner later became Eplan. Today, the company develops one of the worldwide leading software solutions for the engineering of machines, plants and enclosures. With this development, Rittal had reached yet another milestone in the value creation process of its customers.

Rittal conquers a new sector and bridges the gap between industry and IT

The impetus came from the automotive industry. Couldn’t the former PS enclosure, which achieved success on a global scale, be further developed for the data technology sector, or in other words, IT, with corresponding accessories? By doing so, Rittal took its first step as a newcomer to a whole new market segment: information technology. Today, Rittal is one of the leading providers of IT infrastructure solutions of all sizes, from single racks to entire computing centres. With the RiMatrix S, Rittal invented the first standardised computing centre – a scalable solution encompassing power supply, cooling and monitoring. Now the company is taking a further step towards new areas of application, such as energy storage and electric mobility, with the new business unit “Energy & Power Solutions”.

The 4.0 era has arrived, and Rittal is looking beyond control system and switchgear engineering.

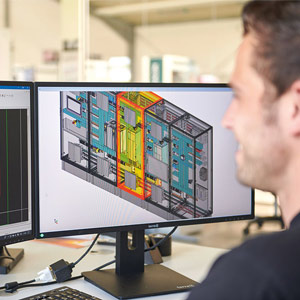

With the start of Industry 4.0, Rittal has set a number of changes in motion – among its customers and its plants. In the first step, the company has worked with Eplan to create a solution for the integrated value chain processes of its customers. With Rittal’s digital twin at the centre, and corresponding interfaces between software and automation, control system and switchgear manufacturers can now plan and produce more efficiently than ever with a comprehensive pool of data to draw from. Rittal forged ahead. Everything needed to be seamlessly integrated into Industry 4.0. The transformation of production involved hundreds of machines and highly complex processes, from the order process and production, all the way through to customer service. It was a success. Now Rittal can well and truly call itself a digital company.

Digitalisation: Nothing is off the rack; everything must be learned from scratch.

In the course of digitalising its new plant in Haiger, Rittal discovered the importance of edge and cloud computing, not only for Rittal, but for other companies too. Together with German Edge Cloud, Rittal has developed a cosmos of edge computing and cloud solutions, tailored to industry requirements, housed in a computing centre, tested in-house and put on the path to standardisation. German Edge Cloud is a founding member of the European data infrastructure consortium, GAIA-X, and a member of the newly founded automotive network, Catena-X. German Edge Cloud fused with iNNOVO Cloud, a highly professional cloud automation company with customers in the banking sector, and IoTOS, a pioneer of edge computing in production.