The electrotechnical documentation and digital twin of a panel and switchgear system now have a new home. Rittal ePocket – the digital wiring plan pocket – is migrating to the cloud. Staff can use their smartphone or tablet to access up-to-date engineering information directly from the shop floor. The digital lifecycle file is replacing the folder of paper documentation and giving the staff responsible for plants and machinery new flexibility for operations and maintenance.

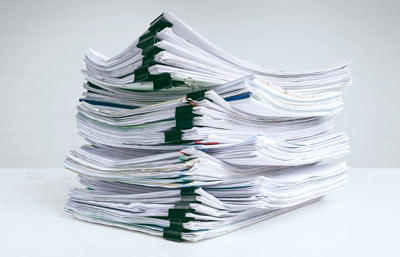

No more piles of paper – Rittal ePocket moves the wiring plan to the cloud.