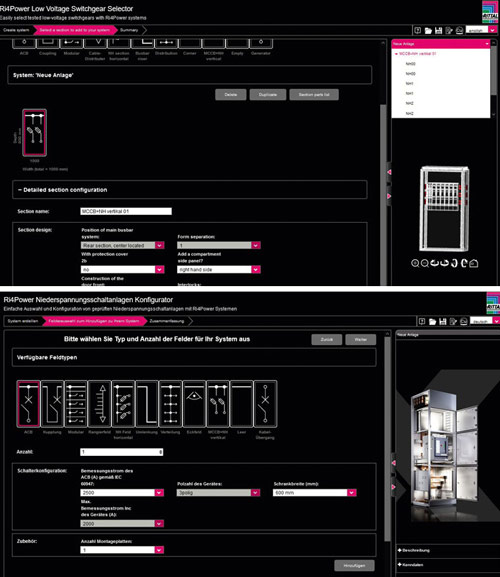

From blast furnaces to paper mills, practically every plant depends heavily on a dependable power supply infrastructure. Switchgear manufacturers design low-voltage switchgear based on project requirements, assemble the units in their own production facilities and commission them on site. In many cases, the quotations they need to provide for projects like these have to be provided in a very short space of time. Their costings are based on the planning for the switchgear, and this is where Rittal comes in, providing valuable support with its Power Engineering planning software and modular VX25 Ri4Power system.

The magazine of Friedhelm Loh Group

The magazine of Friedhelm Loh Group