Text Markus Huneke ––– Photography

The fact steel is so hard to get hold of at the moment is a disaster for many processors. When the pandemic started and the downward economic trend took hold, steel producers took measures to adapt their production to the decline in demand. In 2020, the production of raw steel dropped almost 10 per cent in Germany. When industrial production began to recover at the start of the year, steel production did not follow suit. If they run out of steel, processors risk at best delays, and at worst total stoppage. More than anyone else, it is car makers and their suppliers that are under enormous pressure to keep their assembly lines moving.

Stahlo customers don’t need to worry about reliable, on-time deliveries. Quite the opposite, in fact. The team led by CEO Oliver Sonst is continuing to deliver agreed quantities as arranged. “Despite the coronavirus, we are managing to supply our partners dependably. We don’t have access to any more than we had planned for, either, but what we have planned is getting to us,” explains Sonst. How is it working? “The key to success is actually quite simple – we have excellent, long-established contacts with our suppliers and we stick to the agreements we have made. The dependability of the plants is a huge asset for us,” emphasises the CEO.

NO DISRUPTION, PLEASE!

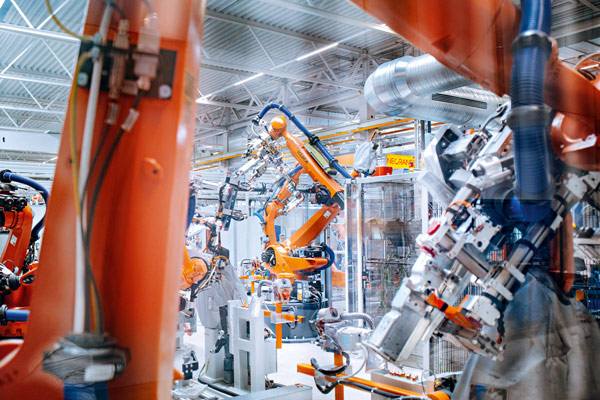

As the most important steel supplier to Rittal and many of its suppliers, Stahlo is a crucial link in the supply chain. Reliability is also a top priority for Meleghy Automotive, a tier 1 supplier to companies including Volkswagen.

Founded in 2012, the company very rapidly established itself as a direct supplier to OEMs, providing structural components and welded assemblies made of steel, stainless steel and aluminium. It also supplies steel processors, including Rittal. Meleghy Automotive has positioned itself perfectly for the growing electromobility market thanks to its four sites in Germany, two of which are very close to the Stahlo sites in Gera and Dillenburg. Among other things, the high-tech processor manufactures floor assembly elements for the ID.4, the first fully electric SUV from Volkswagen. “We are an important link in the automotive supply chain. If one of our components is unavailable, the bodywork can’t be built. That means the flow of materials from us to VW mustn’t be disrupted in any way,” says Dr Gyula Meleghy, CEO of the Meleghy International Group, setting out the permanent challenge.

PARTNER FOR BOTTLENECKS

If the material flow were to be disrupted, the downtime in production would lead to high costs. That has not yet happened at Meleghy Automotive, but the company is certainly feeling the effects of the reduced capacity among steel producers. “It’s taking a huge amount of effort to maintain supplies and get the materials we need on time,” says Dr Meleghy. This shows just how much a partnership is worth. Stahlo has been a long-standing supplier to Meleghy Automotive for many years.

It provides preliminary materials, predominantly in the form of slitted coils, and does so dependably, to the desired quality standards and by the agreed delivery date. “Stahlo is an important partner for us. I’m not just talking about the quality of the products and punctuality, but everything around that, too, such as support during bottlenecks,” emphasises Dr Meleghy.

The supply chain between the two partners has been stable throughout the coronavirus period, too. “Despite the pandemic, everything is going very well between Stahlo and Meleghy and there hasn’t been any notable disruption. That is a huge positive for us, particularly in the present times,” points out Dr Meleghy.